-

Stepper Motor Driver Expansion Board | A4988/8825 Driver Module for 3D Printer 42 Stepper MotorStepper Motor Driver Expansion Board | A4988/8825 Driver Module for 3D Printer 42 CH Stepper Motor This A4988 / DRV8825 Stepper Motor Driver Expansion Board for 3D Printer Parts is used to extend the A4988 or DRV8825 stepper motor driver module. You can use A4988...

- Rs. 62

Rs. 87- Rs. 62

- Unit price

- per

Save Rs. 25 -

2WD Smart DIY Robot Car Plastic Chassis Kit2WD Smart DIY Robot Car Plastic Chassis Kit This is a 2-wheel smart robot car chassis kit, featuring 2 pairs of BO motors and wheels. All components in the DIY Car kit are high-quality, ensuring reliable performance. The chassis is transparent, offering a clear...

- Rs. 232

Rs. 324- Rs. 232

- Unit price

- per

Save Rs. 92 -

YS-DIV268N-5A Hybrid Stepper Motor Driver 5A | Single Axis TB6600 0.2-5A Two Phase Hybrid Stepper Motor Driver ControllerYS-DIV268N-5A Hybrid Stepper Motor Driver 5A | Single Axis TB6600 0.2-5A Two Phase Hybrid Stepper Motor Driver Controller TB6600 Stepper Motor Driver is an easy-to-use professional stepper motor driver, which can control a two-phase hybrid stepper motor. It is compatible with Arduino and other microcontrollers that can output a 5V...

- Rs. 753

Rs. 1,049- Rs. 753

- Unit price

- per

Save Rs. 296 -

Jigo 12V 0.15A CPU FanJigo 12V 0.15A CPU Fan This is the Jigo 12V 0.15A CPU fan, This Dc cooling fan blow air along the axis of the fan or parallel to the track of the blade axis. Dc fans are found in a variety of applications, including...

- Rs. 86

Rs. 123- Rs. 86

- Unit price

- per

Save Rs. 37 -

4 Wheel Drive Gray Chassis with Castor Wheel Slot4 Wheel Drive Gray Chassis with Castor Wheel Slot This is the 4 Wheel Drive Gray Chassis, It can either be used in skid steel configuration (4 motors) or differential configuration (2 rear wheels + 1 front castor wheel). The body contains perforated holes for...

- Rs. 136

Rs. 189- Rs. 136

- Unit price

- per

Save Rs. 53 -

24V DC 4020 Centrifugal Cooling Fan with XH2.54-2P 30CM Cable24V DC 4020 Centrifugal Cooling Fan with XH2.54-2P 30CM Cable This 24V DC 4020 hydraulic centrifugal cooling fan is built with premium, high-temperature-resistant materials for exceptional durability. It’s perfect for cooling heat sinks on hot ends, 3D prints, and various other applications. The 24V...

- Rs. 109

Rs. 199- Rs. 109

- Unit price

- per

Save Rs. 90 -

Coin Type Micro Vibration MotorCoin Type Micro Vibration Motor This Flat 1034 Mobile Phone Vibration Motor is a shaftless vibration motor which is fully-enclosed with no exposed moving parts. Its small size (10 mm diameter, 3.4 mm height) and shaftless design mean you can mount it on a PCB or...

- Rs. 19

Rs. 30- Rs. 19

- Unit price

- per

Save Rs. 11 -

12V DC Solenoid for Electric Door Lock12V DC Solenoid for Electric Door Lock This DC 12V solenoid lock can be used for locking doors, iron luggage, file cabinets, and storage shelves. The electric solenoid door lock assembly is a great fit for several DIY Arduino-based projects. It is steady, durable,...

- Rs. 301

Rs. 403- Rs. 301

- Unit price

- per

Save Rs. 102 -

HG7881 H-Bridge 4CH DC - 2CH Stepper Motor Driver BoardHG7881 H-Bridge 4CH DC - 2CH Stepper Motor Driver Board This is the HG7881 H-Bridge Stepper Motor Driver Board, which can drive 4 dc motors, or two 4-wire 2-phase stepper motors. This motor drive module comes with its own four hg7881 chips. The module...

- Rs. 193

Rs. 346- Rs. 193

- Unit price

- per

Save Rs. 153 -

100 RPM- STRAIGHT SINGLE SHAFT BO motor100 RPM Straight Single Shaft BO motor This 100 rpm BO motor straight single shaft gives good torque and rpm at lower operating voltages. A small shaft with matching wheels gives an optimized design for your application or robot. Mounting holes on the body...

- Rs. 55

Rs. 69- Rs. 55

- Unit price

- per

Save Rs. 14 -

MKS OSC V1.0 Stepper Motor Drive Simple Controller Pulse PWM Signal Generator Module Speed Control 8-24VMKS OSC V1.0 Stepper Motor Drive Simple Controller Pulse PWM Signal Generator Module Speed Control 8-24V This MKS OSC Stepper Motor Controller Pulse PWM Speed Reversing Module generates pulses that are used as a signal for stepper drivers. The stepper motor must be equipped...

- Rs. 528

Rs. 649- Rs. 528

- Unit price

- per

Save Rs. 121 -

85MM Rubber Large Robot Smart Car Wheel Blue Color85MM Rubber Large Robot Smart Car Wheel Blue Color The 85MM Rubber Large Robot Smart Car Wheel in Blue Color is designed to provide excellent performance and durability for robot projects. With a tyre featuring a sponge liner for added strength, this DIY car...

- Rs. 290

Rs. 399- Rs. 290

- Unit price

- per

Save Rs. 109 -

Hobbywing 5L Brushless Water Pump 10A 14S V1 for AgricultureHobbywing 5L Brushless Water Pump 10A 14S V1 for Agriculture The Hobbywing 5L Brushless Water Pump is a high-performance, compact solution designed specifically for precision agricultural applications. Powered by a brushless motor, this pump operates efficiently on a wide voltage range of 12-14S (DC...

- Rs. 6,599

Rs. 8,999- Rs. 6,599

- Unit price

- per

Save Rs. 2,400 -

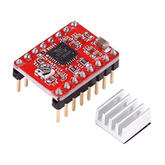

A4988 Stepper Motor Driver Module with Heat Sink For 3D Printer (Red)A4988 Stepper Motor Driver Module with Heat Sink For 3D Printer (Red) A4988 Stepper Motor Driver is a complete micro-stepping motor driver with a built-in translator for easy operation. The product can be full, half, 1/4, 1/8, and 1/16 step mode to operate bipolar stepper...

- Rs. 68

Rs. 101- Rs. 68

- Unit price

- per

Save Rs. 33 -

3-6V Mini Submersible Water Pump3-6V Mini Submersible Water Pump If you're in search of an efficient and affordable water pumping solution, the Mini Micro Submersible Water Pump is your answer. Operating on a 2.5 ~ 6V power supply, it's versatile and suitable for users of all ages. Our...

- Rs. 39

Rs. 59- Rs. 39

- Unit price

- per

Save Rs. 20 -

Monster Motor Driver Shield VNH2SP3014A (Peak 30A)Monster Motor Driver Shield VNH2SP3014A (Peak 30A) The Monster Moto Shield VNH3SP30 Motor Driver is a more powerful version of our Ardumoto motor driver shield. We replaced the L298 H-bridge with a pair of VNH3SP30 full-bridge motor drivers for this Monster Moto Shield. We've...

- Rs. 1,546

Rs. 1,850- Rs. 1,546

- Unit price

- per

Save Rs. 304 -

Black Metal ChassisBlack Metal Chassis This is the Black Metal Chassis, which is commonly used as the mechanical frame structure of mobile robots. It is the robot's backbone, where we arrange and connect everything, such as motors, sensors, and wheels. It serves as the foundation for...

- Rs. 150

Rs. 199- Rs. 150

- Unit price

- per

Save Rs. 49 -

N20 shaft motor 600 RPM - 12VN20 shaft motor 600 RPM - 12V The N20-12V-600 RPM Micro Metal Gear Motor is a compact yet powerful motor with all-metal gears that are durable and resistant to wear and tear. It can serve as an excellent replacement for a rusty or damaged...

- Rs. 224

Rs. 349- Rs. 224

- Unit price

- per

Save Rs. 125 -

DC Mini Submersible Water Pump Motor 12VDC Mini Submersible Water Pump Motor 12V This DC Mini Submersible Water Pump Motor 12V.The pump can be used with an Aquarium or any other small solar-based pumping application. It can be also used with a Sanitizer Dispenser. This pump is completely submersible. DC Powered, can...

- Rs. 274

Rs. 399- Rs. 274

- Unit price

- per

Save Rs. 125 -

23HS5628 Nema 23 Stepper Motor23HS5628 Nema 23 Stepper Motor The 23HS5628 Nema 23 Stepper Motor is a prodigious contraption of unparalleled power and reliability, perfectly suited for a multitude of applications. Its uncanny ability to deliver smooth and consistent torque at high speeds, thanks to its bipolar configuration...

- Rs. 1,163

Rs. 1,455- Rs. 1,163

- Unit price

- per

Save Rs. 292

Best Price Guarantee

Ready Stock for Bulk Purchase

Dedicated Account Managers

5% GST Benefits for Eligible SEZ and Edu

Technical Support Available

1-Year Manufacturer Warranty