-

200 RPM Single Shaft L- Shaped BO Motor200 RPM Single Shaft L- Shaped BO Motor This 200 RPM Single Shaft L- Shaped BO Motor gives good torque and rpm at lower operating voltages, which is the biggest advantage of these motors. This BO motor is a Low-cost geared DC Motor. It...

- Rs. 72

Rs. 99- Rs. 72

- Unit price

- per

Save Rs. 27 -

150 RPM BO Motor- L Shape150 RPM BO Motor- L Shape This 150 RPM L- Shaped BO Motor gives good torque and rpm at lower operating voltages, which is the biggest advantage of these motors. This BO motor is a Low-cost geared DC Motor. It is an alternative to...

- Rs. 53

Rs. 79- Rs. 53

- Unit price

- per

Save Rs. 26 -

Ultra-silent 4-layer Substrate MKS-LV8729 Stepper Motor Driver with Heat SinkUltra-silent 4-layer Substrate MKS-LV8729 Stepper Motor Driver with Heat Sink The Ultra quiet LV8729 4-layer Substrate Stepper Motor Driver Module with 128 subdivisions is used in 3d printers and is a Best suited Moter Driver for Nema stepper motor whose current is less than...

- Rs. 639

Rs. 882- Rs. 639

- Unit price

- per

Save Rs. 243 -

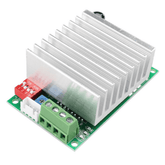

TB6600 Stepper Motor Driver Controller 8~50V 4.5ATB6600 Stepper Motor Driver Controller 8~50V 4.5A TB6600 stepper motor Driver Controller 4.5A 8~50V TTL 16 Micro-Step CNC Single-Axis Based on the TB6600HG chip, the new BL-TB6600-V1.2 driver model replaces the popular BL-TB6560-V2.0 driver.This driver controller is suitable for building not only amateur CNC...

- Rs. 630

Rs. 972- Rs. 630

- Unit price

- per

Save Rs. 342 -

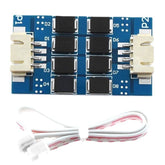

TL-Smoother Eight Chip Module DFORCE Vibration Pattern Filter with CableTL-Smoother Eight Chip Module DFORCE Vibration Pattern Filter with Cable TL Smoother Addon Module Board Kit for 3D Printer Pattern Elimination Motor Clipping Filter. This product mainly aims at the ripple generated by parallel 3D printer printing, especially the effect of using 8825 drive...

- Rs. 116

Rs. 173- Rs. 116

- Unit price

- per

Save Rs. 57 -

8025 12V DC Cooling Fan8025 12V DC Cooling Fan This is a High-Quality 8025 cooling fan, which consists of a 4-pole Brushless DC Motor with a precise vapor bearing system, this cooling fan can deliver an airflow up to 8.0 CFM, which is sufficient enough to keep the...

- Rs. 179

Rs. 199- Rs. 179

- Unit price

- per

Save Rs. 20 -

240mm Aluminium Water Cooling Block240mm Aluminium Water Cooling Block The 40x200 mm Aluminium Water Cooling Block Head is the best solution to keep electronic devices cool and performing at their best. This cooling blockhead has top-quality construction and impressive features. It's crafted from heavy-duty aluminum and ensures durability...

- Rs. 649

Rs. 799- Rs. 649

- Unit price

- per

Save Rs. 150 -

40mm Aluminium Alloy Water Cooling Block40mm Aluminium Alloy Water Cooling Block The water cooling block is manufactured with aluminium and is designed with a 40mm dimension. It has internal extrusions for optimum internal flow. Applicable to computer CPU water, industrial inverter driver, laser head cooling, industrial control cabinet cooling....

- Rs. 289

Rs. 399- Rs. 289

- Unit price

- per

Save Rs. 110 -

BO Wheel (White)BO Wheel (White) This is a high-quality and lightweight BO wheel. The body of this BO wheel is made up of plastic which makes it very lightweight and rotates freely while the grip material is made up of rubber which provides excellent grip on...

- Rs. 13

Rs. 25- Rs. 13

- Unit price

- per

Save Rs. 12 -

DC Submercible Aquarium Pump 6V-12V 5W 500L/HDC Submersible Aquarium Pump 6V-12V 5W 500L/H Flow adjustable water pump is designed fully submersible for both fresh water and saltwater. This pump creates water flow and aerates your aquarium to simulate a natural ocean/river environment. The pump is a must-have accessory for your...

- Rs. 319

Rs. 499- Rs. 319

- Unit price

- per

Save Rs. 180 -

9-60V 10A DC Motor PWM Speed Controller9-60V 10A DC Motor PWM Speed Controller The 10A PWM DC Motor Speed Regulator Module 9 -60V is designed for brushed DC motors (or DC loads) rated at 10A. It comes with a metal shell and a connective label, making it very simple to...

- Rs. 506

Rs. 599- Rs. 506

- Unit price

- per

Save Rs. 93 -

A3967 Stepper Motor DriverA3967 Stepper Motor Driver This A3967 Stepper Motor Driver For Arduino is the most recent version of EasyDriver v44, which was created in collaboration with Brian Schmalz. When compared to previous versions, it offers more flexibility and control over your stepper motor. It is...

- Rs. 211

Rs. 289- Rs. 211

- Unit price

- per

Save Rs. 78 -

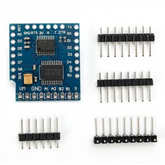

Wemos D1 Mini I2C Dual Motor Driver ShieldWemos D1 Mini I2C Dual Motor Driver Shield The TB6612FNG Wemos D1 Mini I2C Dual Motor Driver Shield, a reliable solution for efficient motor control. With its I2C interface and 15V power supply, this shield ensures precise control and optimal performance. The versatile output...

- Rs. 179

Rs. 229- Rs. 179

- Unit price

- per

Save Rs. 50 -

Robocraze Micro Air Pump MotorRobocraze Micro Air Pump Motor This is Mitsumi MAP-AM-265 Micro Air Pump Motor, this pump has stable and reliable performance, excellent quality, and longer service life. Features: High-Quality Pump Operating Voltage 6VDC Low Noise Operation Durable and Longer Lasting Small in Size Applications: Medical Equipment Health...

- Rs. 205

Rs. 341- Rs. 205

- Unit price

- per

Save Rs. 136 -

4.3 Kgf-cm Servo Motor (ES3001)4.3 Kgf-cm Servo Motor (ES3001) This is ES3001 servo motor, This servo motor has an operating voltage of 4.8V~6.0V, It equips sophisticated internal circuitry that provides good torque, holding power, and faster updates in response to external forces, You can control this servo motor with Arduino which...

- Rs. 688

Rs. 1,037- Rs. 688

- Unit price

- per

Save Rs. 349 -

Robocraze DC6V 100rpm GM12-N20 Miniature Gear Motor with Metal GearRobocraze DC6V 100rpm GM12-N20 Miniature Gear Motor with Metal Gear This N20-6V-100 Rpm Micro Metal Gear Motor has small volume, torsion big, all-metal gear, durable, not easy to wear. Great replacement for the rusty or damaged DC geared speed reduce motor on the machine. Widely...

- Rs. 269

Rs. 299- Rs. 269

- Unit price

- per

Save Rs. 30 -

YS-DIV268N-5A Hybrid Stepper Motor Driver 5A | Single Axis TB6600 0.2-5A Two Phase Hybrid Stepper Motor Driver ControllerYS-DIV268N-5A Hybrid Stepper Motor Driver 5A | Single Axis TB6600 0.2-5A Two Phase Hybrid Stepper Motor Driver Controller TB6600 Stepper Motor Driver is an easy-to-use professional stepper motor driver, which can control a two-phase hybrid stepper motor. It is compatible with Arduino and other microcontrollers that can output a 5V...

- Rs. 999

Rs. 1,299- Rs. 999

- Unit price

- per

Save Rs. 300 -

24V DC 4020 Centrifugal Cooling Fan with XH2.54-2P 30CM Cable24V DC 4020 Centrifugal Cooling Fan with XH2.54-2P 30CM Cable This 24V DC 4020 hydraulic centrifugal cooling fan is built with premium, high-temperature-resistant materials for exceptional durability. It’s perfect for cooling heat sinks on hot ends, 3D prints, and various other applications. The 24V...

- Rs. 113

Rs. 199- Rs. 113

- Unit price

- per

Save Rs. 86 -

Coin Type Micro Vibration MotorCoin Type Micro Vibration Motor This Flat 1034 Mobile Phone Vibration Motor is a shaftless vibration motor which is fully-enclosed with no exposed moving parts. Its small size (10 mm diameter, 3.4 mm height) and shaftless design mean you can mount it on a PCB or...

- Rs. 20

Rs. 30- Rs. 20

- Unit price

- per

Save Rs. 10 -

HG7881 H-Bridge 4CH DC - 2CH Stepper Motor Driver BoardHG7881 H-Bridge 4CH DC - 2CH Stepper Motor Driver Board This is the HG7881 H-Bridge Stepper Motor Driver Board, which can drive 4 dc motors, or two 4-wire 2-phase stepper motors. This motor drive module comes with its own four hg7881 chips. The module...

- Rs. 205

Rs. 346- Rs. 205

- Unit price

- per

Save Rs. 141

Best Price Guarantee

Ready Stock for Bulk Purchase

Dedicated Account Managers

5% GST Benefits for Eligible SEZ and Edu

Technical Support Available

1-Year Manufacturer Warranty