-

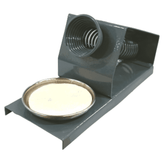

SP-9 Sonal Soldering Iron Stand with Sponge TraySP-9 Sonal Soldering Iron Stand with Sponge Tray The 2-in-1 multi-functional metal soldering iron stand allows you to safely put the soldering iron on the stand so you can concentrate on your work with a smart 2-in-1 design, base comes with a round soldering...

- Rs. 279

Rs. 349- Rs. 279

- Unit price

- per

Save Rs. 70 -

Basic Soldering Iron Tip Holder StandBasic Soldering Iron Tip Holder Stand The Basic Soldering Iron Tip Holder Stand is a practical accessory designed to safely hold a hot soldering iron during use. Made with a sturdy metal coil and stable base, it helps prevent accidental burns and protects your...

- Rs. 27

Rs. 49- Rs. 27

- Unit price

- per

Save Rs. 22 -

Noel Soldering Iron Stand for 25W Soldering IronsNoel Soldering Iron Stand for 25W Soldering Irons The Noel Soldering Iron Stand for 25W Soldering Irons is designed to securely hold 25W or lower wattage soldering irons during use. The sturdy metal base ensures stability, while the spring holder provides a safe and...

- Rs. 50

Rs. 64- Rs. 50

- Unit price

- per

Save Rs. 14 -

Noel Soldering Iron Stand Super Deluxe for 30w-75w Soldering IronNoel Soldering Iron Stand Super Deluxe for 30w-75w Soldering Iron Noel Soldering Iron Stand Super Deluxe is designed for enhanced durability and user comfort. Built to support 30W-75W soldering irons, it features a sturdy powder-coated iron base with a unique bent design for added...

- Rs. 102

Rs. 149- Rs. 102

- Unit price

- per

Save Rs. 47 -

Soldering Iron StandSoldering Iron Stand This soldering iron stand is best suited for the 25W soldering iron. The function of serving as a basic soldering iron stand for 25-watt soldering irons is fulfilled by this product. The base of the Soldering iron stand comprises of heavy-duty metal and...

- Rs. 61

Rs. 71- Rs. 61

- Unit price

- per

Save Rs. 10 -

Sonal SP-7 Soldering Iron StandSonal SP-7 Soldering Iron Stand This is a Sonal SP-7 Soldering Iron Stand with a heavy-duty metal base. This model features a reinforced spring safety holder, which prevents flex from getting entangled with spring. This simple soldering iron stand composed of a reinforced spring holder....

- Rs. 56

Rs. 69- Rs. 56

- Unit price

- per

Save Rs. 13 -

Sonal SP-3 Soldering Iron StandSonal SP-3 Soldering Iron Stand This is a Sonal SP-3 Soldering Iron Stand with a heavy-duty metal base. This model features a reinforced spring safety holder, which prevents flex from getting entangled with spring. This simple soldering iron stand is composed of a reinforced...

- Rs. 79

Rs. 99- Rs. 79

- Unit price

- per

Save Rs. 20 -

Soldron Soldering Iron Stand with SpongeSoldron Soldering Iron Stand with Sponge Its a stable well supported soldering iron stand. Can hold, most of the SOLDRON & other make soldering irons with mesh type hollow iron holder. A sponge for cleaning the iron comes attached to the base. High quality...

- Rs. 349

Rs. 420- Rs. 349

- Unit price

- per

Save Rs. 71 -

Sonal SP-8 Soldering Iron Stand with Sponge TraySonal SP-8 Soldering Iron Stand with Sponge Tray The beautifully designed soldering iron stand with scraper is essential for incredible results without moistening during fast soldering. When using lead-free soldering, there may be a reinforced oxide formation on the surface of the soldering tip,...

- Rs. 215

Rs. 299- Rs. 215

- Unit price

- per

Save Rs. 84

for additional 5% discount! + Redeem RC COINS 👇