-

Soldering Paste (50 gm)Soldering Paste (50 gm) This Quickfix soldering paste flux is ideal for soldering wide electric and electronic components & bonding will be free from faulty soldering problems. The flux has stable performance, volatile, long life cycle, the amount of Provincial, non-toxic, odourless, safe to...

- Rs. 41

Rs. 69- Rs. 41

- Unit price

- per

Save Rs. 28 -

Noel Soldering Flux Paste 10gm Pack - YellowNoel Soldering Flux Paste 10gm Pack - Yellow Noel Yellow Soldering Paste/Flux (10gm Pack) is crafted with superior quality activators and additives to enhance your soldering experience. This flux ensures cleaner, more efficient soldering by leaving no black marks, creating minimal smoke, and leaving no...

- Rs. 26

Rs. 39- Rs. 26

- Unit price

- per

Save Rs. 13 -

Noel Pure Copper Desoldering Wick/WireNoel Pure Copper Desoldering Wick/Wire Noel Pure Copper Desoldering Wick/Wire is expertly designed for precision desoldering in electronics manufacturing and repair. Made from 100% pure copper and coated with a specialized grade RMA flux, it ensures faster solder absorption and cleaner joints. Its fuller...

- Rs. 40

Rs. 54- Rs. 40

- Unit price

- per

Save Rs. 14 -

Noel Heat Sink Compound Paste (Thermal Grease)Noel Heat Sink Compound Paste (Thermal Grease) Noel Heat Sink Compound Paste (Thermal Grease) is a high-performance thermal adhesive that improves heat conductivity. It is also known as Thermal grease/ Heat paste/ CPU paste/ Thermal compound/ Thermal paste. It eliminates air gaps between the...

- Rs. 40

Rs. 54- Rs. 40

- Unit price

- per

Save Rs. 14 -

Noel Solder Paste (Flux) 10gm Pack - WhiteNoel Solder Paste (Flux) 10gm Pack - White Noel’s soldering flux paste is an innovative product designed for high-quality soldering and desoldering operations. With carefully formulated additives and activators, it ensures optimal performance in various soldering tasks. The white solder paste is developed using...

- Rs. 26

Rs. 54- Rs. 26

- Unit price

- per

Save Rs. 28 -

Soldering Cleaning Sponge for Soldering Irons/Work Stands (7x5.5cm)Soldering Cleaning Sponge for Soldering Irons/Work Stands (7x5.5cm) The 7CM x 5.5CM Soldering Cleaning Sponge for Soldering Irons/Work Stands is a high-quality, durable cleaning tool designed to keep your soldering tips in top condition. Ideal as a replacement for old sponges, it effectively removes...

- Rs. 18

Rs. 24- Rs. 18

- Unit price

- per

Save Rs. 6 -

Soldering Cleaning Sponge (5.5x5.5cm)Soldering Cleaning Sponge (5.5x5.5cm) The 5.5X5.5CM Soldering Cleaning Sponge is an excellent tool for maintaining clean and effective soldering tips. Designed as a high-quality, low-cost replacement for old sponges, it effectively removes all solder residue, ensuring better soldering results. When wet, the sponge expands...

- Rs. 23

Rs. 29- Rs. 23

- Unit price

- per

Save Rs. 6 -

Soldering Paste (15g)Soldering Paste (15 gm) This solder paste flux is ideal for soldering wide electric and electronic components & bonding will be free from faulty soldering problems. The flux has stable performance, volatile, long life cycle, the amount of Provincial, non-toxic, odorless, safe to use,...

- Rs. 17

Rs. 30- Rs. 17

- Unit price

- per

Save Rs. 13 -

Non-Corrosive Soldering Paste Flux (500g)Non-Corrosive Soldering Paste Flux (500g) This solder paste flux is ideal for soldering wide electric and electronic components & bonding will be free from faulty soldering problems. The flux has stable performance, volatile, long life cycle, the amount of Provincial, non-toxic, odorless, safe to...

- Rs. 370

Rs. 425- Rs. 370

- Unit price

- per

Save Rs. 55 -

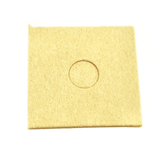

SOLDRON SPONGE SQUARE SSSSOLDRON Sponge Square SSS Soldering Bit Cleaning Sponge The soldering bit cleaning sponge is porous, so it holds water. Rubbing a hot soldering iron tip on a wet sponge causes the solder to contract at a different rate than the soldering iron, helping to knock...

- Rs. 28

Rs. 34- Rs. 28

- Unit price

- per

Save Rs. 6 -

Soldering Tip Cleaning Brass Wire SpongeSoldering Tip Cleaning Brass Wire Sponge This is Soldering Tip Cleaning Brass Wire Sponge. There is no need to add water so as to avoid the cooling of the soldering head and the explosion of tin beads so as to improve the welding/ Soldering...

- Rs. 195

Rs. 240- Rs. 195

- Unit price

- per

Save Rs. 45 -

Soldron Soldering and Desoldering Flux (10g)Soldron Soldering and Desoldering Flux (10g) Liquid flux removers for your soldering projects. Our no-clean liquid flux has superior fluxing ability after soldering the residue is non-corrosive, non-conductive, and moisture- and fungus-resistant. Circuit Specialists carry the liquid flux removers with variable valves that enable...

- Rs. 105

Rs. 149- Rs. 105

- Unit price

- per

Save Rs. 44 -

Acrylcoat Conformal Coating for PCB Assemblies Solderable 500mlAcrylcoat Conformal Coating for PCB Assemblies Solderable 500ml Conins Acrylcoat is a high quality, transparent, acrylic base, conformal coating PCBs. Acrylcoat ensures protection for PCBs and components against Moisture, dust, oxidation etc. in extremely humid conditions. It is very fast drying (<10 mts.) and gives a...

- Rs. 457

Rs. 599- Rs. 457

- Unit price

- per

Save Rs. 142 -

Soldron Soldering and Desoldering Flux - 200mlSoldron Soldering and Desoldering Flux - 200ml Soldron Soldering and Desoldering Flux - 200ml is a very high quality professional, non-corrosive and non-conductive flux. Ideal for all soldering applications. It causes no damage to PCBs even if a residue is left on after soldering. Soldron...

- Rs. 509

Rs. 560- Rs. 509

- Unit price

- per

Save Rs. 51

for additional 5% discount! + Redeem RC COINS 👇