I Tried Building a Gesture-Controlled Robot… Using Only ₹400 Worth of Parts

Summary

When I first saw gesture-controlled robots online, I assumed they cost thousands. Professional devices responding to hand movements? Expensive lab technology.

Three weeks later, I'm controlling a robot by tilting my hand. Left tilt, robot turns left. Forward, robot drives forward. Total cost? ₹387.

Friends assumed I bought a premium kit. Truth? I built a gesture robot India using components costing less than a movie ticket.

Low cost robotics India isn't about cheap knockoffs. It's about understanding which components deliver functionality for minimum price.

The Real Problem

Most tutorials for gesture robot India assume complete kits or expensive sensors. MPU6050 modules, wireless transmitters, motor drivers—"this costs ₹2,000 minimum."

But the concept is simple. Accelerometer detects hand tilt. Data transmits wirelessly to robot. Robot interprets direction and moves motors.

Once you understand this, you don't need premium components. You need functional ones.

What Changed My Perspective

I saw an ADXL335 accelerometer listed for ₹80. "Detects tilt in X, Y, Z axes."

If this ₹80 sensor detected hand tilt, couldn't I use that data to control a robot wirelessly?

I made a minimum budget parts list. No fancy chassis. No expensive modules. Just functional components.

Total: ₹387.

Complete Parts List

Transmitter (Hand-Worn):

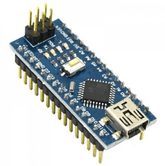

- Arduino Nano clone (₹120)

- ADXL335 accelerometer (₹80)

- 433MHz RF transmitter (₹40)

- 9V battery (₹50)

- Mini breadboard (₹25)

- Jumper wires (₹15)

Receiver (Robot):

Arduino Nano clone (₹120) - Wait, budget exceeded

First problem. Two Arduinos exceeded the budget. Solution? I already owned one from previous projects. Starting fresh? Budget ₹507, or use Arduino Uno (₹280) on receiver and ATtiny85 (₹80) on the transmitter.

Actual Receiver:

- 433MHz RF receiver (₹40)

- L298N motor driver (₹80) - Over budget again

- I swapped to L293D chip (₹35). Less current but sufficient for small motors.

Robot Base:

- Two DC motors with wheels (₹90)

- Cardboard chassis (₹0 - recycled)

- 9V battery for motors (₹50)

- Jumper wires (₹15)

- Revised Total: ₹387 (one Arduino already owned)

- Complete beginners: expect ₹507 for two Arduinos.

Building the Transmitter

Understanding ADXL335

Accelerometer outputs analog voltage based on tilt. Tilt left, X-axis voltage drops. Tilt right, voltage increases. Forward tilt changes Y-axis.

Arduino reads voltage changes and converts to movement commands.

Wiring

ADXL335 to Arduino Nano:

- VCC to 3.3V (not 5V—sensor is 3.3V rated)

- GND to Ground

- X-axis to A0

- Y-axis to A1

433MHz RF transmitter:

- VCC to 5V

- GND to Ground

- Data to Digital Pin 12

- Power from 9V battery to Arduino VIN.

The Code

Read X-axis from A0. Read Y-axis from A1. Determine direction. Send via RF transmitter.

- If X < 400: LEFT

- If X > 600: RIGHT

- If Y < 400: FORWARD

- If Y > 600: BACKWARD

- Else: STOP

VirtualWire library handled RF communication. About 40 lines total.

Problem Nobody Mentions

First test sent garbage data. Commands randomly switched. Robot spazzed.

Accelerometers are noisy. They detect every tiny shake. Needed threshold—only register tilt exceeding certain degrees for 200ms.

Added smoothing code. Problem solved.

Building the Receiver

Creating Chassis

Cut cardboard 15cm x 10cm. Hot-glued motors to sides. Attached wheels. Added battery holder on top.

Not pretty. Functional. ₹0 cost.

Wiring

433MHz RF receiver to Arduino:

- VCC to 5V

- GND to Ground

- Data to Pin 12

L293D motor driver (16 pins, initially confusing):

- Pins 1,9: motor enable (Arduino PWM for speed)

- Pins 2,7,10,15: motor direction (Arduino digital pins)

- Pins 3,6,11,14: connect to motors

- Pins 4,5,12,13: Ground

- Pin 16: power (5V)

- Pin 8: motor power (separate 9V battery)

The Code

Receive RF command. Translate to motor movements.

FORWARD: Both motors forward

BACKWARD: Both motors reverse

LEFT: Left motor stop, right forward

RIGHT: Right motor stop, left forward

STOP: Both motors stop

VirtualWire library. About 50 lines.

Unexpected Problem

Motors barely moved. They hummed but didn't rotate.

Issue? 9V battery couldn't supply enough current. High voltage, low current capacity. Motors need current.

Solution: Three AA batteries in series (4.5V total). Lower voltage, higher current. Motors spun perfectly.

Tutorials skip this. They say "use 9V battery" without mentioning current requirements.

Testing and Refinement

First test felt incredible. Tilted hand left. Robot turned left. Tilted forward. Robot drove forward.

But problems emerged:

Delayed Response

2-3 second lag sometimes. Frustrating.

Cause: Transmitting every 500ms to save power. Changed to 100ms. Nearly instant response.

Overcorrection

Slight hand movements caused aggressive robot movements. Turned too sharply.

Solution: PWM speed control. Set motors to 60% speed for smoother control.

Range Limitation

433MHz modules claim 100-meter range. Reality? 15 meters with obstacles. 30 meters line-of-sight.

Fine for indoor use. Worth knowing for expectations.

What This Taught

This build proved that low-cost robotics in India is viable.

Motion detection translated from hand to robot. Wireless communication worked with budget components. Motor control responded accurately.

Now expensive gesture devices don't look like magic. Accelerometer, wireless transmitter, motor driver. Components for under ₹400.

The One Rule

Low-cost robotics India succeeds when you understand component function over brand names.

Don't need SparkFun accelerometers. Generic ADXL335 works identically. Don't need official Arduinos. Clones function the same.

Sensor detects → Transmitter sends → Receiver moves motors.

This works whether components cost ₹400 or ₹4,000. Expensive versions add features. Core functionality? Identical.

Why Try This

If "₹400 gesture robot sounds too good to be true," I understand. I was skeptical.

But barriers dropped. Components available locally. Code libraries handle RF communication. Motor control is straightforward.

Hardest part is troubleshooting unexpected issues. But those teach practical skills tutorials skip.

Getting Started

Order components from list above. Budget ₹400-₹500 depending on what you own. Don't overthink which modules. Any compatible accelerometer and RF pair works.

Watch one tutorial to familiarize connections. But expect your build to differ. Chassis dimensions, wire routing, component placement—unique to your build.

Give yourself a weekend. Goal isn't perfection. Goal is functional gesture control.

When you tilt your hand and watch your robot respond—everything clicks.

The Bottom Line

My desk has a cardboard robot responding to hand gestures. Cost ₹387. Looks homemade. Works beautifully.

The solution wasn't expensive kits. It was understanding which parts deliver core functionality.

The gesture robot on recycled cardboard proved something. Low cost robotics india isn't compromising quality. It's prioritizing function over form.

You don't need ₹2,000 for gesture control. You need ₹400 and willingness to troubleshoot.