How One ₹150 Motor Can Teach You More Than a Semester of Theory

Summary

Engineering theory often feels detached from reality, leaving students "booksmart but benchclueless." This post explores how a simple, budget friendly DC motor acts as the ultimate bridge between abstract formulas and physical innovation. We’ll dive into why handson building is the fastest way to master electronics, overcome the "softwarefirst" struggle, and achieve true concept clarity.

The "Aha!" Moment vs. The Textbook

I’ve spent my fair share of time navigating complex simulations in Proteus or Multisim. Digital lines are clean. They don't have resistance unless you click a box. They don't generate heat. They don't make noise. But there is a massive, visceral difference between seeing a "current" line move on a digital graph and feeling a DC motor vibrate in your palm as it draws more power than your circuit can handle.

When you start looking into the world of dc motor projects India based hobbyists are creating, you realize that the most profound lessons don't come from the most expensive equipment. They come from the simplest interactions.

The first time I hooked up a standard yellow BO motor to a battery, I didn't just see motion; I saw the physical manifestation of electrical energy. In my "Machines I" lectures, "Stall Current" was just a term in a textbook. On my desk, it was the moment my motor stopped spinning because I gripped the shaft too hard, and my jumper wires started getting suspiciously warm.

That five minute troubleshooting session taught me more about power consumption and thermal limits than an entire week of lectures. This is the essence of electronics learning. It’s not about the consumption of facts. It’s about the application of logic to physical matter.

The Software Developer’s Struggle with Hardware

As someone who feels much more at home debugging a Python script than stripping a 22 gauge wire, the transition to hardware was humbling. In the software world, if something goes wrong, you get a StackTrace. You get a line number. You get a helpful error message like NullPointerException.

In the hardware world, your error message is silence. Or worse, the "Magic Smoke", that distinct smell of a fried component that tells you you’ve just made a very expensive (or in this case, a ₹150) mistake.

When I started my first electronics learning journey, I expected the hardware to behave as logically as my code. I thought, "If I send a HIGH signal to this pin, the motor MUST spin." But hardware doesn't care about your "musts." It cares about contact resistance, electromagnetic interference (EMI), and gravity. For a developer, learning that a loose ground wire is the hardware equivalent of a missing semicolon is a rite of passage.

It forces you to think about the "Physical Layer" of the OSI model in a way that code never does. You begin to respect the power of a pullup resistor and realize that "floating pins" are the ghosts that haunt your logic.

Bridging the Gap: Practical Exposure to Real-World Variables

Practical exposure is often treated as a secondary "lab" requirement in traditional education, relegated to a three-hour slot once a week. But in reality, it should be the foundation. When you are building dc motor projects India, you encounter real world variables that textbooks conveniently ignore to make the math look pretty:

- Friction and Inertia: In a textbook, a motor starts instantly. In reality, it takes a moment to overcome static friction. This taught me why we need a higher "starting torque" and why my robot wouldn't move at low PWM values even though the code said it should. You learn that code isn't just about logic; it's about timing and physical momentum.

- Voltage Drop: I remember being baffled why my Arduino would reset every time the motor started. I had the code right! But I didn't understand that the motor was "stealing" all the current during its startup surge, dropping the voltage below the threshold my microcontroller needed to stay "alive." This is where you learn the critical importance of decoupling capacitors and separate power rails.

- Electrical Noise: Motors are noisy not just audibly, but electrically. They kick back "back EMF" into your circuit. This led me to discover the "Flyback Diode," a component I’d ignored in class but suddenly became my best friend when I needed to protect my Microcontroller boards.

Solving these issues provides a level of concept clarity that no lecture can replicate. For instance, understanding Pulse Width Modulation (PWM) becomes incredibly intuitive when you’re actually writing code to make a motor spin slower or faster. You aren't just changing a duty cycle variable; you are watching a physical object respond to the average power you’re feeding it. This feedback loop turns a student into a builder.

The "Pro" Setup Organically

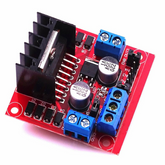

If you’re just starting out, don't feel like you need a laboratory grade bench power source or a high end oscilloscope. Some of my best learning happened with just a breadboard, a handful of jumper wires, and a basic L298N motor driver.

I remember trying to build a simple line-follower robot. I had the logic perfectly mapped out in my head, if sensor A sees black, turn motor B. Simple, right? But the robot kept veering off and spinning in circles. It wasn't a "code" problem; it was a weight distribution and mechanical alignment problem. One motor was spinning slightly faster than the other because of manufacturing tolerances a "bug" that doesn't exist in the digital world.

That realization that hardware constraints dictate software design is a high level engineering insight. It’s why we have if statements that account for "overshoot" or "coasting." Using a curated Motor Starter Kit or high-quality sensor modules can help bridge this gap by ensuring your components are compatible, allowing you to focus on the physics and the creative problem solving rather than wondering if your cheap transistor is blown.

From Theory to Innovation: The Scalability of a Motor

One ₹150 motor is a gateway drug to more complex robotics projects. The logic remains remarkably scalable. Once you understand how to control the speed and direction of one DC motor, you suddenly understand the fundamental principles behind a 4WD rover, a CNC machine, or even a 3D printer.

The beauty of DC motor projects in India is their accessibility and low barrier to entry. You can start by making a DIY desk fan to survive the Indian summer. Then, you can add a relay to turn it on via your smartphone. Then, you can add an ultrasonic sensor to make it turn off when you leave the chair. Suddenly, you haven't just "learned electronics"; you’ve built a smart home device.

You start seeing the world differently. A broken remote controlled car in the trash isn't garbage anymore, it's a source for a free geartrain, a battery pack, and a potential project chassis. You stop being a consumer of technology and start being a producer of it. This mindset shift is more valuable than any grade on a transcript. You start analyzing everyday objects like an automated sliding door or an electric tooth brush and you can mentally map out the motor driver, the feedback loop, and the microcontroller logic behind them.

Final Thoughts: Your Tony Stark Moment Awaits

You don’t need a fancy degree to start innovating, and you certainly don't need to wait for a professor to give you permission to build. If you’re feeling stuck in the "theory loop," wondering if you’re ever going to use that calculus in real life, go out and get a motor.

Connect it, break it, fix it, and eventually, automate it. That small piece of spinning silicon and copper will teach you more about the soul of engineering than a thousand pages of text ever could. The satisfaction of seeing your code move a physical object, even if it's just a plastic wheel spinning on a messy desk, is the ultimate confidence boost.

That "Tony Stark" moment, where the gap between "this is impossible" and "I can build anything" disappears, is only one successful upload away. In the journey of electronics learning, your greatest teacher isn't a textbook; it's the motor that refuses to spin until you finally understand why. Start small, stay curious, and keep building.