Types of Electric Motor

Summary

Electric Motors are the unsung heroes hidden inside countless devices, diligently converting electrical energy into mechanical motion.

But not all motors are the same. A vast and diverse family of them exists, each engineered for a specific job.

Understanding this variety is key to appreciating the technology that drives our daily lives.

What is an Electric Motor?

An electric motor operates on the principle of electromagnetism, the fundamental relationship between electricity and magnetism.

Imagine holding a compass near a wire with electricity flowing through it; the needle will twitch and turn without any physical contact.

An electric motor harnesses this same force on a much larger and more controlled scale.

It uses electricity to create temporary magnetic fields that push and pull against other magnets, forcing a part of the motor to rotate continuously.

Every electric motor has two essential components: a stator and a rotor. The stator is the stationary outer casing of the motor, which is typically wrapped with coils of wire.

The rotor is the inner shaft that rotates. When electricity is supplied to the coils in the stator, it generates a magnetic field.

This field then interacts with the rotor, which might contain permanent magnets or its own set of coils, creating a force called torque that causes the rotor to spin.

Classification of Electric Motors

The first and most important way to classify the many types of electric motors is by the kind of electrical power they use: Alternating Current (AC) or Direct Current (DC).

AC is the type of power that flows from a wall outlet, where the direction of the current rapidly alternates back and forth.

DC is the type of power you get from a battery, where the current flows steadily in one direction.

This fundamental difference in the nature of the power supply dictates the motor's internal design and operating principle.

An AC motor must be designed to work with a current that is constantly changing its direction, while a DC motor is built for a consistent, unidirectional flow.

This primary division gives rise to two major families of motors, each with its own branches and specializations tailored for different applications, power requirements, and control needs.

Types of AC Motors

AC motors are mainly categorized into two types: synchronous and asynchronous (induction) motors.

- Asynchronous motors include single-phase and three-phase types, with common sub-types being the squirrel-cage induction motor.

- Synchronous motors have rotors that rotate in sync with the stator's magnetic field.

Asynchronous Motors (Induction)

The asynchronous motor, more commonly known as the induction motor, is arguably the most widespread type of motor in the world, powering countless devices in homes and factories.

Its operation is based on the elegant principle of electromagnetic induction. The alternating current in the stator coils generates a magnetic field that rotates.

This moving field sweeps past the rotor, inducing a current within it. This induced current creates the rotor's own magnetic field, which is then pulled along by the stator's rotating field, causing the shaft to spin.

A defining characteristic is that the rotor never quite catches up to the speed of the magnetic field; this speed difference, called "slip," is essential for the induction process to occur.

- Single-Phase Induction Motors: These are the workhorses of residential and light commercial applications, designed to run on the single-phase AC supply common in wall outlets. They are found in devices like refrigerators, fans, and washing machines.

- Three-Phase Induction Motors: Used extensively in industrial settings, these motors operate on a more powerful three-phase AC supply. This type of power naturally generates a smoothly rotating magnetic field, making the motor self-starting, more efficient, and more robust than its single-phase counterpart.

- Squirrel-Cage Rotor: The most common design for an induction motor's rotor is the squirrel-cage. It is named for its simple, rugged construction, which features conductive bars running the length of the rotor, connected by end rings, resembling a hamster wheel.

- Wound Rotor (Slip Ring): A less common variant is the wound rotor motor. This design features actual wire windings on the rotor, which are connected to external resistors through a set of slip rings and brushes. This allows for control over the motor's speed and starting torque.

Synchronous Motors

The other major category within the types of AC motors is the synchronous motor.

True to its name, the rotor of a synchronous motor rotates in perfect synchronization with the stator's rotating magnetic field and, therefore, in lockstep with the frequency of the AC supply.

Unlike an induction motor, there is no slip; the rotor's speed is directly tied to the electrical frequency, making it incredibly stable and predictable.

This characteristic makes this one of the most precise types of electric motor available.

Precise Speed Control: Because they do not slip, synchronous motors are the ideal choice for applications where exact speed regulation is critical, regardless of changes in load. This includes use in high-precision machine tools, robotics, and timing devices like electric clocks.

Rotor Construction: The rotor in a synchronous motor does not rely on induction. Instead, its magnetic field is created either by using permanent magnets or by using windings that require an external DC power source for excitation. This DC supply creates fixed north and south poles on the rotor that are "locked" in step with the stator's rotating magnetic field.

Types of DC Motors

The various types of DC motors are typically classified by how the stator's field winding is electrically connected to the rotor's armature winding.

This internal wiring configuration directly influences the motor's performance characteristics, such as its speed-torque relationship, making different designs suitable for different tasks.

- Series DC Motor: In this design, the field winding is connected in series with the armature winding. This means the same current flows through both. This configuration produces an exceptionally high starting torque, making series motors ideal for applications that need a lot of initial power to get moving, such as automotive starter motors, cranes, and electric traction vehicles.

- Shunt/Parallel DC Motor: Here, the field winding is connected in parallel, or "shunt," with the armature winding. This setup allows the motor to maintain a relatively constant speed even as the load changes. This stable speed characteristic makes them well-suited for applications like industrial machine tools (lathes and drills) and conveyor belts where consistent operational speed is important.

- Compound DC Motors: As the name suggests, this motor is a hybrid that combines both series and shunt field windings. By blending the two designs, compound motors can offer a balance of characteristics—good starting torque like a series motor, but with better speed regulation than a series motor, though not as constant as a pure shunt motor. They are used where high starting torque and reasonably stable speed are both required.

- Permanent Magnet DC Motor (PMDC): This type of motor simplifies the design by eliminating the stator field winding altogether. Instead of an electromagnet, it uses permanent magnets to create the stationary magnetic field. This makes the motor smaller, lighter, and often more efficient since no power is consumed to create the field. PMDC motors are very common in toys, computer disk drives, and automotive applications like windshield wipers and power windows.

Special Types of Electric Motors

Beyond the main AC and DC families, several specialized motors are designed for unique tasks that require more than just simple, continuous rotation.

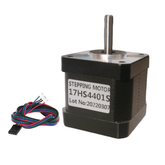

- Stepper Motors: These motors do not spin freely but move in precise, discrete increments or "steps." For each electrical pulse sent by a controller, the motor shaft rotates a fixed, small angle. This allows for incredibly accurate position control without needing a feedback sensor. This is why they are essential in devices like 3D printers, scanners, and CNC machines, where exact positioning is paramount.

- Servo Motors: A servo is not just a motor but a complete closed-loop system. It consists of a motor (AC or DC), a position sensor (an encoder), and a controller. The controller constantly compares the motor's actual position with the desired position and drives the motor to correct any error. Imagine parking a car perfectly in the center of a space by constantly looking and adjusting; a servo does this thousands of times a second. This makes them indispensable for robotics, camera autofocus systems, and remote-controlled aircraft.

Conclusion

The world of electric motors is a testament to specialized engineering, extending far beyond the simple act of making something spin.

From the brute-force simplicity of an industrial induction motor to the high-tech precision of a robotic servo motor, each design is a purpose-built solution to a specific mechanical challenge.

Choosing the correct type of electric motor involves a careful trade-off between power, speed control, efficiency, cost, and longevity.

As our world becomes more automated and electrified, the continued innovation in motor technology will remain a central driver of progress, powering the next generation of machines, vehicles, and robots.