Essential Electronic Components You Need for Every Robotics Project

Summary

Building a robot from scratch can feel overwhelming, especially when you're staring at catalogs full of circuits, sensors, and wires.

But here's the thing: every successful robotics project, whether it's a simple line-following bot or a sophisticated humanoid, relies on a handful of fundamental parts.

Understanding which components form the backbone of your creation makes the difference between a functional machine and a pile of expensive paperweights gathering dust on your workbench.

What is an Electronic Component?

An electronic component is a discrete device or physical entity in an electronic system that affects electrons or their associated fields.

These are the individual building blocks that make up electronic circuits, each serving a specific purpose in controlling, directing, or manipulating electrical current.

Think of them as the alphabet of electronics—individually simple, but capable of creating complex systems when combined thoughtfully.

Electronic components range from passive elements like resistors and capacitors that don't require external power to function, to active components like transistors and integrated circuits that need energy to operate.

In robotics, these components work together to create systems that can sense the environment, process information, make decisions, and execute physical actions.

Without understanding these fundamental parts, building a functional robot becomes nothing more than guesswork.

Different Types of Electronic Components

Electronic components fall into several categories based on their function and behavior in circuits:

Passive Components

- Resistors control current flow and create voltage divisions

- Capacitors store and release electrical energy

- Inductors resist changes in current flow

- These components don't amplify signals but manage electrical energy

Active Components

- Transistors act as switches or amplifiers

- Diodes allow current flow in one direction only

- Integrated circuits perform complex calculations

- These require external power to function

Electromechanical Components

- Motors convert electrical signals into rotational motion

- Servos provide precise angular positioning

- Relays switch high-power circuits mechanically

- Solenoids create linear motion from electrical pulses

Sensors and Input Devices

- Detect physical phenomena like light, temperature, or distance

- Convert environmental data into electrical signals

- Enable robots to perceive and respond to their surroundings

- Form the sensory system of any intelligent robot

List of Essential Electronic Components You Need for Every Robotics Project

Microcontroller or Single-Board Computer

The brain of your robot needs processing power, and that's where microcontrollers or single-board computers come in.

Arduino boards serve as an excellent starting point for beginners, offering easy programming and plenty of input/output pins for connecting sensors and actuators.

For more demanding applications requiring wireless connectivity or complex computations, a Raspberry Pi provides full computer functionality in a compact form factor.

Key considerations when selecting:

- Number of input/output pins available

- Processing speed and memory capacity

- Built-in features like WiFi or Bluetooth

- Programming language support and community resources

- Power consumption requirements

These electronic parts determine your robot's intelligence level. They read sensor data, execute your programmed logic, and send control signals to motors and other outputs. Your microcontroller selection shapes what your robot can accomplish and how complex your programming can become.

Power Supply and Battery Management

Robots need reliable energy, and power systems involve more than just batteries. The power supply acts as the lifeblood of your robotics project, and selecting appropriate components ensures your robot runs smoothly without unexpected shutdowns or component damage.

Essential power components include:

- Battery packs matching voltage requirements (lithium polymer for mobile robots, AA holders for simpler projects)

- Voltage regulators ensuring stable power as batteries discharge

- Power switches for safe on/off control

- Fuses or circuit breakers protecting against short circuits

- DC-DC converters for multiple voltage requirements

Proper power management protects your expensive electronic components from voltage spikes and ensures consistent performance. Include a power indicator LED so you always know when your robot is energized, preventing accidental modifications to live circuits.

Motors and Motor Drivers

Motors transform electrical energy into the mechanical motion that brings robots to life. Different motor types serve different purposes in robotics applications, and understanding their characteristics helps you choose appropriately for your robotic project.

Motor types for robotics:

- DC motors provide continuous rotation for wheels and propellers

- Servo motors offer precise angular positioning for robot arms

- Stepper motors deliver accurate incremental movement

- Gear motors add torque reduction for heavy loads

However, microcontrollers can't directly power motors. They lack sufficient current capacity and risk damage from voltage spikes motors generate.

Motor driver modules like the L298N or more modern DRV8825 chips handle the heavy current while accepting low-power control signals from your microcontroller.

These basic electronics for robotics protect your expensive brain components while giving you speed and direction control over your mechanical systems. Always match motor driver current ratings to your motor specifications with safety margin.

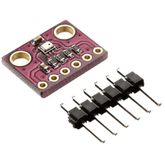

Sensors for Environmental Awareness

Robots that can't sense their surroundings are just remote-controlled STEM toys. Sensors form the perception system that allows robots to gather information about their environment and make intelligent decisions based on that data.

Common sensors in robotics projects:

- Ultrasonic sensors measure distance using sound waves

- Infrared sensors detect objects and follow lines

- Light-dependent resistors track ambient light or light sources

- Gyroscopes and accelerometers provide orientation data

- Temperature and humidity sensors monitor environmental conditions

- Touch sensors detect physical contact or pressure

The sensor suite you choose defines your robot's perception of the world. These robotics project components determine whether your creation blindly follows commands or intelligently responds to its environment.

When selecting sensors, consider detection range, accuracy requirements, response time, and power consumption. Multiple sensor types often work together to provide robust environmental awareness.

Resistors and Capacitors

Resistors might seem boring compared to sensors and motors, but these passive electronic components prevent costly mistakes. They're the unsung heroes that keep circuits functioning reliably under varying conditions.

Resistor applications in robotics:

- Limit current flow to protect LEDs from burning out

- Create voltage dividers for reading analog sensors

- Form pull-up or pull-down circuits ensuring definite digital input states

- Set gain levels in amplifier circuits

- Provide current sensing for motor control

Capacitors store and release electrical charge, smoothing power supply fluctuations that could cause erratic behavior.

Decoupling capacitors placed near integrated circuits filter out electrical noise, while larger electrolytic capacitors help maintain stable voltage when motors suddenly draw heavy current.

These key components for building robots work behind the scenes, ensuring your circuits behave predictably. Keep assorted resistor and capacitor values in your parts inventory. You'll use them constantly.

LEDs and Display Modules

Visual feedback makes debugging infinitely easier and adds polish to finished projects. Indicator lights and displays transform invisible electronic signals into visible information you can interpret at a glance.

Display options for robotics:

- Standard LEDs indicate power status and sensor states

- RGB LEDs create colorful lighting effects

- Seven-segment displays show numbers simply

- LCD character displays present text information

- OLED screens offer high-contrast graphical displays

- LED matrices create animations and simple graphics

Even in headless robots without user interfaces, keeping a few LEDs connected to key signals helps you understand what's happening inside when behavior doesn't match expectations during development.

Status LEDs connected to sensor outputs, motor driver enable pins, and communication activity provide invaluable troubleshooting information without requiring you to connect debugging equipment.

Transistors and Relays

Sometimes you need to control high-power devices or isolate circuits electrically. Transistors act as electronic switches, allowing small microcontroller signals to control larger currents for components like motors or high-power LEDs.

Switching component selection:

- MOSFETs handle heavy loads efficiently with minimal power loss

- Bipolar transistors work well for medium-power applications

- Darlington pairs provide high current gain

- Relays provide mechanical switching with complete electrical isolation

- Solid-state relays offer relay benefits without moving parts

Understanding when to use transistors versus relays forms part of the practical knowledge needed for robot assembly tools and circuit design.

Transistors switch faster and last longer since they have no moving parts, but relays excel at controlling AC power or isolating circuits with vastly different voltage levels.

Wires, Connectors, and Breadboards

The unglamorous reality of robotics involves lots of wiring. Proper interconnection methods determine whether your robot functions reliably or suffers mysterious intermittent failures.

Essential connection components:

- Jumper wires in various lengths for prototyping

- Breadboards enabling circuit building without soldering

- Header pins and sockets for removable connections

- Terminal blocks for permanent wire connections

- Crimp connectors creating reliable wire terminations

- Heat shrink tubing protecting exposed connections

Don't underestimate wire gauge selection. Thin wires work fine for signal connections but overheat and create voltage drops when carrying motor current.

Color-coding wires according to function (red for power, black for ground, other colors for signals) makes troubleshooting vastly easier.

Proper connector selection from your robotics project materials list prevents frustrating intermittent failures caused by loose connections during robot movement. Invest in quality crimping tools as poor connections cause more debugging headaches than almost any other issue.

Voltage Level Shifters and Signal Conditioners

Modern robotics often mixes components operating at different voltages. A 5V Arduino controlling 3.3V sensors or interfacing with 12V motor drivers. Level shifter modules safely translate signals between voltage domains, preventing damage to sensitive components.

Signal management considerations:

- Bidirectional level shifters for I2C and similar buses

- Unidirectional buffers for simple signal translation

- Pull-up and pull-down resistor networks ensuring reliable communication

- Optocouplers providing electrical isolation between circuits

- Low-pass filters removing high-frequency noise

Without these protective measures, connecting a 5V output directly to a 3.3V input could permanently destroy the receiving device. Signal conditioning circuits filter noise from long wire runs or electrically noisy environments filled with switching motors.

These often-overlooked electronic components separate hobbyist projects from professional designs that function reliably in real-world conditions.

Communication Modules

Modern robotics projects often need wireless connectivity for remote control, data logging, or internet integration. Communication capabilities transform standalone robots into networked devices that can coordinate with other systems.

Wireless communication options:

- Bluetooth modules enable smartphone control over short ranges

- WiFi modules connect robots to networks and the internet

- Radio frequency modules provide long-range outdoor communication

- Infrared transceivers offer simple line-of-sight data transfer

- LoRa modules enable ultra-long-range low-power communication

For projects requiring wired communication, serial interfaces, I2C buses, and SPI connections allow multiple microcontrollers or sensors to share data efficiently.

Communication protocols form part of the components needed for robotics projects when building anything beyond the simplest autonomous systems.

Consider data rate requirements, range limitations, power consumption, and whether you need bidirectional communication when selecting modules.

Audio Components and Speakers

Adding sound brings personality to robots and provides non-visual feedback. Small speakers or piezo buzzers can play tones, alert users to errors, or confirm successful operations.

Audio system components:

- Piezo buzzers for simple tones and alerts

- Small speakers for higher quality sound

- Audio amplifier modules increasing signal strength

- Digital audio players for recorded sounds

- Speech synthesis modules enabling robot voice output

For more sophisticated projects, audio amplifier modules let robots play recorded sounds or synthesized speech, creating more engaging human-robot interaction. Audio feedback also serves debugging purposes.

Different tone patterns can indicate various program states or sensor conditions without requiring you to watch a display constantly.

When your hands are busy adjusting mechanical parts, hearing confirmation of sensor triggers or program state changes proves invaluable during testing and calibration.

Conclusion

Building robots requires more than enthusiasm and imagination. It demands understanding the components needed for robotics projects that transform concepts into working machines.

From the microcontroller brain to the motors providing motion, from sensors perceiving the environment to passive components ensuring circuit stability, each element plays a vital role in creating functional robotics systems.

The robotics project materials list outlined here provides the foundation for countless project variations, whether you're building line-following competitors, obstacle-avoiding explorers, or articulated robot arms.

Starting with this foundation of essential parts gives you the building blocks to construct everything from simple educational projects to sophisticated autonomous machines.