Introduction to Capacitors

Summary

Uncover the electrifying world of capacitors with our blog, "Introduction to Capacitors." Delve into the fundamentals as we explore the various types, demystify capacitor specifications, and unveil their versatile applications. Learn the art of capacitor testing and maintenance to ensure peak performance. Whether you're a tech enthusiast or a curious mind, this blog sparks a captivating journey through the heart of electronic components. From powering gadgets to stabilizing circuits, capacitors play a pivotal role. Join us on this electrifying ride, and let's charge up your knowledge! Discover, learn, and spark your curiosity with our comprehensive guide.

Introduction

Capacitors are one of the most ubiquitous passive components found in electrical and electronic circuits. From large power factor correction capacitors in electric utility networks to tiny decoupling capacitors on circuit boards, capacitors perform critical functions in nearly every electronic system. A capacitor is fundamentally a simple device consisting of two conductive plates separated by an insulating dielectric material. When voltage is applied across the plates, opposite electric charges accumulate on each plate to produce an electrostatic field that allows the capacitor to store energy. This stored energy can be quickly discharged to release energy when required in the circuit.

The ability of capacitors to store and release energy as needed makes them ideal for vital roles such as filtering signals, bypassing power supplies, coupling and decoupling circuits, tuning resonant circuits, differentiating and integrating waveforms, and holding voltage levels. Capacitors exhibit the unique ability to pass AC signals while blocking DC signals, enabling extensive usage for AC coupling and bypassing applications. Understanding the operating principles, specifications, types, testing methods, and applications of the diverse capacitors available is essential knowledge for all electrical engineers and circuit designers.

Types of Capacitors

Capacitors are manufactured in an extensive range of shapes, sizes, types, capacitance values, voltage ratings, and package styles tailored for particular applications and operating conditions. They can be broadly categorized based on the dielectric material which determines essential characteristics like maximum operating voltage, capacitance stability, precision, frequency response, equivalent series resistance, and leakage current properties.

Ceramic capacitors

Ceramic capacitors are the most universally used type of capacitor in electronic circuits. Constructed of ceramic materials like porcelain, glass, mica, and titanium dioxide, they offer high-density construction and low cost. Ceramic capacitors classified as Class 1 dielectrics using materials like NP0/C0G are extremely stable with low capacitance change versus temperature fluctuations. But Class 2 ceramic dielectrics like X7R and Y5V offer higher capacitance values with greater variability over temperature and age. In general, ceramic capacitors have lower capacitance ranges up to a few μF but can operate at high voltages and handle high frequencies up to hundreds of megahertz.

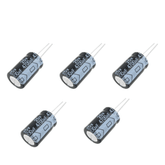

Electrolytic capacitors

Electrolytic capacitors utilize an electrolyte as the dielectric which allows ultrahigh capacitance values reaching thousands of μF in compact sizes. The most common are aluminum electrolytic capacitors with aluminum oxide layer and liquid electrolyte. Tantalum electrolytic capacitors are another popular type, employing a tantalum pentoxide dielectric and manganese dioxide or conductive polymer electrolyte. Their high-density energy storage capacity makes electrolytic capacitors well suited for smoothing, buffering, and power supply filtering roles. However, electrolytic capacitors are polarized components prone to drying out and ageing issues.

Film capacitors

Film capacitors use insulating plastic films like polyester, polypropylene, polystyrene or polycarbonate as the capacitor dielectric. They offer high stability, precision tolerances, and low parasitic elements that allow operation up to gigahertz frequencies. But film capacitors have lower capacitance values than electrolytics and lower working voltages compared to multilayer ceramic capacitors. Common film capacitor types are metallized film and film-foil construction.

Supercapacitors

Supercapacitors, also known as ultracapacitors or electrochemical double layer capacitors (EDLC), contain porous electrodes immersed in electrolyte and provide capacitance values from millifarads to thousands of farads. Their extraordinarily high capacitance allows supercapacitors to rapidly charge and discharge to deliver or absorb high bursts of power. However, they operate over a narrow voltage window of around 2-3V per cell. Supercapacitor applications include regenerative braking energy storage, short-term backup power, and delivering pulsed loads.

Capacitor Specifications

Capacitors have a multifaceted set of electrical and physical specifications that must be scrutinized to determine their suitability for the target application and operating conditions. Key parameters to consider are capacitance value, voltage rating, tolerance, equivalent series resistance (ESR), equivalent series inductance (ESL), temperature coefficient, leakage current, dielectric absorption, lifetime expectancy, size, and cost constraints.

The capacitance, measured in picofarads (pF), nanofarads (nF) or microfarads (μF), indicates the capacitor's ability to store charge. The voltage rating specifies the maximum allowable working voltage that can be applied continuously across the capacitor without dielectric breakdown and failure. All capacitors have a tolerance expressed as +/- a percentage that indicates the potential deviation from the stated capacitance value.

The temperature coefficient specifies the degree to which the capacitance drifts with varying ambient temperature. Equivalent series resistance (ESR) represents the resistive losses exhibited by the capacitor plates and terminals, causing power dissipation and limiting high frequency response. Similarly, equivalent series inductance (ESL) is the self-inductance exhibited at high frequencies that can cause impedance rise and resonance issues.

Leakage current is the small external current that flows through the dielectric due to insulation resistance breakdown. Dielectric absorption is the tendency of a capacitor to retain a residual charge after discharge due to polarization effects in the dielectric material. High insulation resistance, low leakage current, and negligible dielectric absorption are desirable capacitor attributes.

Capacitors also have an optimal working frequency range determined by the physical construction and materials used. For instance, electrolytic capacitors have poor high frequency characteristics whereas film and ceramic capacitors can operate well into the megahertz and gigahertz ranges respectively. Considering size restrictions, operating temperature range, expected lifetime, and cost constraints along with the electrical performance specifications allows selection of the optimal capacitor solution for the intended function.

Capacitor Applications

The wide spectrum of electrical characteristics makes capacitors suitable for countless diverse applications across the entire gamut of electronics systems. They perform critical roles in circuits for amplifiers, power supplies, motors, audio equipment, radars, control systems, radio equipment, and high-speed communication networks.

In amplifier and signal processing circuits, capacitors serve for coupling stages, bypassing supply rails, generating frequency selective filters to pass desired signals while blocking unwanted ones, differentiating and integrating waveforms, and shaping pulse response. High frequency decoupling capacitors provide localized charge storage to stabilize voltage levels supplying sensitive integrated circuits prone to latchup or logic errors.

In regulated power supplies, capacitors help filter ripple voltage and noise from rectified supplies, provide surge current during dynamic loads, damp input supply variations, and suppress conducted electromagnetic interference through bypassing and filtering. In audio systems, polypropylene, polystyrene, and specialty film capacitors help reproduce superior sound quality and minimize distortion at sensitive amplifier inputs. Variable capacitors allow tuning frequency in radio receivers and transmitters by changing capacitance electronically or mechanically.

Capacitive position and displacement sensors detect proximity, acceleration, fluid levels, and other physical measurements based on capacitance change between capacitor plates. Energy storage applications like camera flash units and pulsed lasers utilize specialized capacitors for rapidly discharging stored energy to produce intense bursts of light or power. Supercapacitors assist hybrid vehicles through regenerative braking energy capture and torque assist during acceleration from standstill. RF transmitters and receivers employ low impedance film and ceramic capacitors to bypass supply rails for enhanced high frequency stability.

Capacitors fulfill indispensable roles including AC coupling, DC blocking, bypassing, decoupling, frequency selective filtering, differentiating, integrating, waveshaping, snubbing, charge storage, tuning, timing circuits, and sensing across the entire gamut of electronics applications spanning consumer, commercial, industrial, communications, automotive, aerospace, instrumentation, appliances, IoT devices, and more. Mastering capacitor selection and application is imperative to harness their full capabilities.

Capacitor Testing and Maintenance

Because capacitors perform crucial functions where failure can have serious consequences, testing capacitors before installation and periodically during operation is imperative to ensure they meet the expected specifications and operate reliably throughout their anticipated lifetime. Some simple testing techniques to evaluate capacitors are measuring capacitance value, insulation resistance, leakage current, and equivalent series resistance (ESR).

Capacitance can be easily measured with basic multimeters, handheld capacitance meters, or benchtop LCR meters. Testing capacitance at the circuit's operating frequency provides insights into frequency-dependent capacitance effects. Insulation resistance is measured by applying a suitable DC voltage like 100V across the capacitor terminals and measuring the resulting leakage current, which should ideally be in the nanoampere range for most capacitors. High leakage current signifies deteriorating insulation and imminent dielectric breakdown.

ESR checking involves measuring the capacitor's complex impedance at its self-resonant frequency and deriving the equivalent series resistance value, which contributes to heating and reduced capacitor life if excessive. Leakage current can also be directly measured by fully charging the capacitor with its working voltage applied, allowing it to stabilize, then measuring the tiny quiescent current across the capacitor. Polarity verification and inspecting for any sign of electrolyte leakage are also critical steps when testing polarized capacitors like electrolytics.

More extensive capacitor testing can be conducted using impedance analyzers, which apply an AC signal over a wide frequency range to graph the capacitor's impedance signature and derive multiple parameters. Environmental stress testing including voltage, vibration, shock, and temperature cycling helps uncover latent defects and weaknesses. When using multiple capacitors in filter designs, matching critical parameters between the parallel capacitors prevents imbalanced current distribution problems. Following evidence-based testing methods validates that capacitors meet the system's lifetime and performance requirements.

Preventive capacitor maintenance involves monitoring ripple currents and voltage levels applied to avoid exceeding rated limits, limiting inrush currents during equipment turn-on, providing adequate airflow cooling across power capacitors, and storing components in ideal conditions to prevent moisture ingression. Many electrolytic capacitors can benefit from periodic reforming and reconditioning procedures to extend operational life. With prudent testing and preventive maintenance, capacitors can deliver reliable performance over their expected service life.

Conclusion

In conclusion, capacitors are indispensable passive components that fulfill vital roles including bypassing, decoupling, AC coupling, DC blocking, smoothing, filtering, waveshaping, differentiating, integrating, tuning, sensing, and energy storage across the entire spectrum of electronics applications. An enormous range of capacitors are available spanning from tiny surface-mount ceramic capacitors to large power film capacitors, each optimized for specialized applications based on their distinct capacitance value, voltage rating, frequency response, precision, ESR performance, leakage current, and stability characteristics.

Understanding the operating principles, specifications, types, testing techniques, and applications of the diverse capacitor families is essential knowledge for circuit designers and electrical engineers seeking to select the optimal capacitor solution for the function and operating conditions involved. Careful capacitor selection followed by thorough testing and preventive maintenance helps ensure capacitors deliver reliable, long-term functionality in the myriad electronics systems that society relies on for transportation, communications, health services, entertainment, and commercial operations. Mastering identification, application, testing, and maintenance best practices allows unlocking the full benefits of capacitors in modern electrical engineering.