10 Cool Projects to Print with the Bambu Lab A1 Mini

Summary

The desktop 3D printing landscape has evolved dramatically, and the Bambu Lab A1 Mini stands as a testament to how far we've come.

This compact powerhouse transforms your imagination into a tangible reality with precision that rivals machines costing three times as much.

After weeks of testing various projects, I've discovered that this printer excels not just at basic prototyping, but at creating genuinely useful objects that solve real-world problems.

What makes the A1 Mini special is the way it democratizes complex manufacturing, bringing industrial-grade precision to your home workshop.

Whether you're an educator looking to inspire students, a maker pushing creative boundaries, or a professional prototyping for the next breakthrough product, this machine delivers consistent results that exceed expectations.

In this comprehensive guide, we'll explore ten fascinating projects that showcase the A1 Mini's capabilities while providing practical value for your daily life.

Each project has been tested extensively to ensure reliable printing on this specific machine.

Why Choose the Bambu Lab A1 Mini for 3D Printing Projects?

Before diving into specific projects, it's worth understanding what makes the Bambu Lab A1 Mini 3D printer particularly suited for challenging prints.

The automatic calibration system eliminates the tedious setup that traditionally plagued desktop 3D printing.

I've watched this machine self-calibrate dozens of times, consistently achieving first-layer adhesion that would make veteran makers jealous.

The enclosed chamber design maintains thermal stability that's crucial for precision work. Temperature fluctuations that ruin complex prints simply don't occur here.

The result is dimensional accuracy that approaches injection-molded quality, opening up possibilities for functional parts rather than just decorative objects.

Perhaps most importantly, the intelligent print monitoring system prevents those heartbreaking failures that waste hours of time and expensive filament.

The 3D printing machine actually watches itself work, pausing when problems arise rather than continuing to create expensive plastic spaghetti.

Best Settings for Printing Projects on the A1 Mini

Achieving consistent, high-quality results with your A1 Mini requires understanding the optimal settings for different project types.

After extensive testing across various materials and geometries, I found these configurations deliver the most reliable outcomes.

PLA Projects (Decorative and Basic Functional)

- Nozzle Temperature: 215°C

- Bed Temperature: 60°C

- Layer Height: 0.2mm for general use, 0.15mm for fine details

- Print Speed: 80mm/s outer perimeters, 120mm/s infill

- Retraction: 0.8mm at 35mm/s

PETG Projects (Functional Parts and Outdoor Use)

- Nozzle Temperature: 250°C

- Bed Temperature: 80°C

- Layer Height: 0.2mm standard, 0.25mm for faster drafts

- Print Speed: 60mm/s outer perimeters, 100mm/s infill

- Retraction: 1.2mm at 25mm/s

ABS Projects (High-Temperature Applications)

- Nozzle Temperature: 260°C

- Bed Temperature: 100°C

- Chamber Temperature: 40°C (automatic on A1 Mini)

- Layer Height: 0.2mm for optimal strength

- Print Speed: 70mm/s outer perimeters, 110mm/s infill

Best 10 Bambu Lab A1 Mini Project Ideas

Project 1: Articulated Desk Lamp with Custom LED Mount

This sophisticated desk lamp represents one of the most popular Bambu Lab A1 Mini projects, demonstrating the printer's precision in creating complex multi-part assemblies with tight tolerances.

The design features seven articulated joints that move smoothly without binding, while the integrated LED mount provides optimal lighting control and heat dissipation.

The snap-fit joint system eliminates hardware requirements while maintaining professional durability, making this an excellent choice among beginner 3D printer projects despite its apparent complexity.

Steps to Complete the Project:

- Download the multi-part STL files and arrange them optimally on the build plate to minimize support material usage.

- Print all components using PLA at 0.2mm layer height with 20% gyroid infill for optimal strength-to-weight ratio.

- Enable tree supports for overhanging joint sections to ensure clean surfaces without difficult cleanup.

- Post-process each joint by carefully removing support material and testing fit before proceeding to assembly.

- Assemble the lamp segments in sequence, starting from the base and working toward the LED mount.

- Install your chosen LED strip into the custom mount, ensuring proper wire routing through the articulated sections.

- Test all joint movements and adjust if necessary by light sanding of contact surfaces.

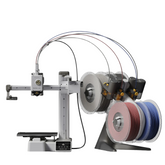

Project 2: Modular Storage System with Magnetic Connections

This versatile organization system transforms any workspace with infinitely reconfigurable storage solutions and stands among the most practical 3D printing projects with Bambu A1 Mini.

Each component features precisely engineered magnet slots that create surprisingly strong connections while allowing instant reconfiguration.

The modular approach means you can start small and expand the system as your storage needs grow, making it perfect for creating a custom desk organizer 3D model tailored to your specific requirements.

Steps to Complete the Project:

- Begin by printing the base components including drawer units and shelf brackets using PETG for enhanced durability.

- Purchase 6mm neodymium magnets to fit the precisely dimensioned pockets built into each component.

- Print specialized compartments for electronics, tools, or office supplies based on your specific organizational needs.

- Test-fit all magnet pockets before installing magnets to ensure proper seating without gaps or binding.

- Install magnets using a small amount of cyanoacrylate adhesive to secure them permanently in place.

- Create cable management channels by printing the routing accessories and integrating them into your workspace layout.

- Assemble your initial configuration and test the magnetic connections for strength and alignment.

- Expand the system over time by printing additional components that follow the same dimensional standards.

Project 3: Precision Measuring Tools for Workshop Use

Transform your A1 Mini 3D printer into a precision instrument manufacturer with this collection of accurate measuring tools.

These workshop-grade implements rival commercial alternatives while solving measurement challenges that standard tools can't address.

The dimensional accuracy achievable makes these tools suitable for quality control in professional applications and represents some of the most impressive Bambu Lab A1 Mini projects for functional use.

Steps to Complete the Project:

- Start with gauge blocks as accuracy references, printing them with measuring surfaces parallel to the build plate.

- Use 0.15mm layer height and enable dynamic flow control for maximum dimensional precision.

- Print digital caliper holders and custom measuring fixtures oriented to minimize layer line interference.

- Post-process all measuring surfaces by light sanding with fine-grit paper to remove layer lines.

- Verify accuracy using known reference standards or existing precision measuring equipment.

- Create custom fixtures for specific measurement tasks by designing around your particular workshop needs.

- Test each tool's repeatability by taking multiple measurements of the same object and comparing results.

- Document the accuracy limitations of each tool for future reference and quality control purposes.

Project 4: Functional Mechanical Clock Movement

This engineering masterpiece pushes the boundaries of what desktop 3D printing can achieve in precision mechanical systems and exemplifies creative 3D printing ideas at their finest.

The complete clock movement features an escapement mechanism, pendulum timing system, and gear train—all printed as functional components that keep accurate time.

This project serves as both a timepiece and a demonstration of advanced manufacturing capabilities possible with Bambu Lab A1 Mini projects.

Steps to Complete the Project:

- Begin by printing the gear train components with teeth oriented flat to the build plate for optimal surface finish.

- Use minimal tree supports on critical surfaces to avoid cleanup difficulties that could affect gear mesh quality.

- Print the escapement mechanism with extreme care, as this timing-critical component requires perfect dimensional accuracy.

- Assemble the gear train first, testing each gear mesh for smooth operation without binding or excessive backlash.

- Install the escapement mechanism and verify proper timing by observing the tick rate and consistency.

- Mount the pendulum assembly and adjust the length to achieve accurate timekeeping over extended periods.

- Fine-tune the entire mechanism by carefully deburring gear teeth with small files and adjusting clearances.

- Test the completed clock for several days to verify timing accuracy and make final adjustments as needed.

Project 5: Electronic Project Enclosures with Perfect Fits

Create professional-grade enclosures for your electronic projects that fit perfectly on the first print attempt using your Bambu A1 Mini 3D printer.

These custom housings feature integrated mounting systems, ventilation patterns, and secure closures that protect sensitive electronics while maintaining easy access for modifications.

The precision eliminates the frustrating iteration cycle typical of custom enclosure development, making these among the most practical printable home accessories you can create.

Steps to Complete the Project:

- Measure your electronic components precisely using digital calipers to create accurate 3D models.

- Design the enclosure with 0.2mm clearance around all components to allow for thermal expansion and easy assembly.

- Incorporate mounting posts and screw bosses directly into the design to eliminate loose hardware and improve reliability.

- Add ventilation patterns using hexagonal grids that maximize airflow while maintaining structural integrity.

- Print the enclosure body and lid separately to ensure optimal surface finish on both internal and external surfaces.

- Test-fit all electronic components before final assembly to verify clearances and access requirements.

- Install heat-set inserts in mounting points for professional-grade threaded connections that won't strip over time.

- Apply labels or surface textures as needed to create a finished appearance suitable for professional applications.

Project 6: Kinetic Sculpture with Moving Parts

This mesmerizing art piece combines aesthetic appeal with mechanical complexity, creating hypnotic motion patterns from simple motor input and representing one of the most visually striking Bambu Lab A1 Mini projects.

Seven interconnected movement systems operate simultaneously with different timing cycles, demonstrating sophisticated engineering principles while serving as an engaging conversation piece.

The sculpture showcases the A1 Mini's ability to print functional mechanical assemblies with multiple moving parts, making it an excellent articulated toy 3D print for adults.

Steps to Complete the Project:

- Print all moving components with careful attention to support placement to avoid affecting mechanical surfaces.

- Use tree supports strategically positioned to provide necessary scaffolding while minimizing cleanup effort on critical joints.

- Assemble the base mechanism first, ensuring all gear trains mesh properly before adding upper movement systems.

- Install the drive motor and test basic motion before connecting the more complex linkage systems.

- Add each movement layer sequentially, testing operation at each stage to identify and resolve binding issues.

- Apply light graphite powder lubrication to high-wear joints to improve long-term operation and reduce noise.

- Balance the moving masses to minimize vibration and ensure smooth operation across all speed ranges.

- Run the completed sculpture continuously for several hours to verify reliability and make final adjustments.

Project 7: Garden Automation Components

Bring precision manufacturing to outdoor applications with these weather-resistant automation components that showcase the versatility of 3D printing projects with Bambu A1 Mini.

The irrigation controller housing and sensor mounts survive full seasonal cycles while maintaining dimensional accuracy and weather sealing.

PETG material selection provides UV stability and temperature cycling resistance essential for reliable outdoor operation, and you can create custom miniature planters 3D design components to complement your automation system.

Steps to Complete the Project:

- Print all outdoor components using PETG material for superior UV resistance and temperature stability.

- Design sealed joints using O-ring grooves or compression seals to prevent moisture ingress over time.

- Create mounting systems that accommodate standard irrigation fittings while providing adjustment mechanisms for precise positioning.

- Install cable management systems that protect wiring from weather while allowing seasonal system removal.

- Test all sealing systems with water exposure before installing expensive electronic components.

- Apply UV-resistant coatings to exposed surfaces if additional protection is desired for extreme environments.

- Install the complete system and monitor performance through initial weather cycles to verify reliability.

- Document mounting procedures and seasonal maintenance requirements for future reference and system expansion.

Project 8: Educational STEM Demonstration Models

Transform abstract engineering concepts into tangible learning tools that students can manipulate and explore, making these perfect STEM 3D models for kids and educational environments.

These demonstration models include gear ratio illustrators, structural engineering examples, and physics principle demonstrations designed to withstand enthusiastic classroom handling while maintaining educational effectiveness.

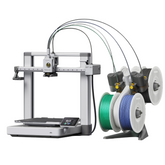

When equipped with AMS Lite, you can create multi-color 3D prints with AMS Lite that help students distinguish different functional components through color coding.

Steps to Complete the Project:

- Print gear cases using transparent filament to allow observation of internal mechanisms while protecting delicate components.

- Use color-coding strategies by printing different functional elements in contrasting colors to help students understand system relationships.

- Increase infill percentages to 30-40% for enhanced durability under repeated student handling and classroom use.

- Create modular designs that allow students to reconfigure systems and observe the effects of different arrangements.

- Develop accompanying documentation that explains the engineering principles demonstrated by each physical model.

- Test all models with actual students to identify potential failure points and improve design robustness.

- Create storage solutions that protect the models while keeping them easily accessible for classroom demonstrations.

- Train educators on proper use and maintenance procedures to maximize the lifespan of these valuable teaching tools.

Project 9: Replacement Parts for Household Items

Transform your Bambu A1 Mini 3D printer into your personal parts department by creating exact replacements for broken household items.

This reverse-engineering approach often produces parts with superior durability compared to original components, while eliminating the frustration and expense of sourcing obscure replacement parts from manufacturers.

These practical applications represent some of the most valuable Bambu Lab A1 Mini projects for everyday problem-solving, and you can even create decorative multi-color fridge magnets 3D print replacements for damaged refrigerator accessories.

Steps to Complete the Project:

- Carefully measure the broken component using digital calipers to create accurate reference dimensions.

- Create detailed 3D models that replicate the original geometry while identifying potential improvement opportunities.

- Select materials that offer superior properties compared to the original part, such as PETG for enhanced durability.

- Print test components to verify fit and function before committing to final material and settings choices.

- Test the replacement part under actual use conditions to verify performance and identify any needed modifications.

- Document successful repairs with photos and measurements for future reference and potential reuse.

- Create a library of common household parts that can be quickly reprinted when similar failures occur.

- Share successful designs with the maker community to help others solve similar household repair challenges.

Project 10: Multi-Part Mechanisms and Assemblies

Push the boundaries of print-in-place technology with this complex planetary gearbox that prints as a complete unit with all internal components, representing one of the most technically challenging Bambu Lab A1 Mini projects.

This advanced project demonstrates how modern 3D printing can create sophisticated mechanical systems without traditional assembly or adjustment procedures, achieving performance that matches conventionally manufactured alternatives.

For those with AMS Lite systems, this project offers excellent opportunities for AMS Lite filament switching projects by using different colors for various gear components to visualize the mechanical relationships, and you could even create accompanying keychain STL files featuring miniature versions of the gearbox mechanism.

Steps to Complete the Project:

- Design the complete gearbox assembly using print-in-place techniques that eliminate traditional assembly steps.

- Calculate proper clearances between all moving parts to ensure smooth operation while maintaining structural integrity.

- Print the entire mechanism in a single job using carefully planned support structures that don't interfere with internal movement.

- Remove support material systematically, working from external surfaces toward internal components to avoid damage.

- Test initial movement gradually, starting with gentle manual rotation to identify any binding or interference issues.

- Apply light oil to high-load surfaces to accelerate the break-in process and achieve optimal mechanical performance.

- Document the gear ratios and mechanical specifications achieved for comparison with traditional manufacturing methods.

- Run extended testing cycles to verify long-term reliability and identify any wear patterns that might require design modifications.

Conclusion

The Bambu Lab A1 Mini transforms complex manufacturing concepts into accessible desktop reality.

These ten projects demonstrate how precision engineering, thoughtful design, and reliable hardware combine to create genuinely useful objects that solve real-world problems.

Whether you're building precision measuring tools for professional use or kinetic sculptures for artistic expression, the A1 Mini delivers consistent results that exceed expectations.

Start with any project that matches your interests and skill level—each success builds confidence for tackling increasingly ambitious challenges.

Ready to start your own precision manufacturing journey? Robocraze offers competitive pricing and expert support for the complete Bambu Lab printer lineup, including the A1 Mini and AMS Lite systems.

Robocraze’s technical team provides comprehensive and ongoing support to ensure you get the most from your investment.

With fast shipping and genuine Bambu Lab products, Robocraze makes it easy to transform your creative ideas into tangible reality.

Excerpt

Frequently Asked Questions

1. Is the Bambu Lab A1 Mini good for multi-color 3D printing?

Yes, the A1 Mini excels at multi-color printing when paired with the AMS Lite system. The combination allows for automatic filament switching during prints, enabling vibrant multi-color designs and functional color-coded components. The enclosed chamber design maintains consistent temperatures across different filament types, ensuring reliable layer adhesion in multi-material prints.

2. What filament types are compatible with the A1 Mini?

The A1 Mini supports a wide range of filaments including PLA, PETG, ABS, ASA, and TPU. PLA works best at 215°C with 60°C bed temperature, PETG requires 250°C nozzle and 80°C bed, while ABS needs 260°C nozzle temperature with 100°C heated bed. The enclosed chamber design particularly benefits temperature-sensitive materials like ABS by maintaining stable printing conditions.

3. How long do these projects typically take to print?

Print times vary significantly based on project complexity and settings. Simple projects like keychains or desk organizers take 2-4 hours, while complex assemblies like the mechanical clock or kinetic sculpture require 8-12 hours. Multi-part projects may need 15-20 hours total when accounting for all components, though they can often be printed in batches to optimize time efficiency.

4. Can I customize these designs before printing?

Absolutely! Most project files can be modified using standard 3D modeling software like Fusion 360, Tinkercad, or Blender. You can adjust dimensions, add personal engravings, modify mounting holes, or change aesthetic elements to match your specific needs. The modular nature of many designs makes customization particularly straightforward for storage systems and organizational components.

5. Do I need to calibrate the printer before printing these models?

The A1 Mini's automatic calibration system handles most setup requirements, including bed leveling and flow rate adjustment. However, for precision projects like measuring tools or tight-tolerance assemblies, manual verification of bed adhesion and first-layer quality is recommended. The machine typically maintains calibration across multiple prints, requiring intervention only when changing filament types or after extended use.

6. What is AMS Lite and how does it work with the A1 Mini?

AMS Lite is Bambu Lab's automatic material system that enables seamless multi-color and multi-material printing. It holds up to four filament spools and automatically switches between them during printing based on the sliced model requirements. The system works by retracting the current filament, loading the next specified material, and purging the nozzle to ensure clean color transitions, making complex multi-color projects achievable without manual intervention.

7. What makes the Bambu Lab A1 Mini ideal for beginners?

The Bambu Lab A1 Mini is perfect for beginners due to its user-friendly interface and compact design. It’s easy to set up and operate, offering features like automatic bed leveling and intuitive controls. The reliability of this 3D printer allows newcomers to focus on creativity without getting bogged down by complicated processes.

8. Which filament works best for these projects?

For most projects with the Bambu Lab A1 Mini, PLA filament is the best choice. It's easy to work with, offers excellent print quality, and is less prone to warping. Other filaments like PETG can also be used for functional parts, but beginners should start with PLA for a smoother experience.

9. How long does it take to print these models?

Print times with the Bambu Lab A1 Mini vary based on the model’s complexity and size. On average, small prints take between 30 minutes to a few hours. Larger or more intricate models can take several hours, so it's essential to optimize settings for efficiency without compromising quality.

10. Can I modify the 3D designs before printing?

Yes, you can easily modify 3D designs before printing with the Bambu Lab A1 Mini. Software such as Tinkercad or Blender allows you to alter STL files. Customizing designs lets you adjust sizes, shapes, or add personal touches, enhancing your printing experience.

11. Are these projects suitable for kids?

Absolutely! The Bambu Lab A1 Mini's easy controls and safety features make it suitable for kids, especially with adult supervision. Engaging in 3D printing can also enhance their creativity and problem-solving skills while introducing them to technology in a fun way.

12. Where can I download STL files for these projects?

You can find STL files for various projects on websites like Thingiverse and MyMiniFactory. These platforms offer a vast selection of designs, from toys to functional items, making it easy to start printing with your Bambu Lab A1 Mini.

13. How to ensure perfect prints with Bambu Lab A1 Mini?

To ensure perfect prints, start with a clean print bed and level it properly. Use high-quality filament and set the correct temperature settings for your material. Regularly check your printer's mechanical components and run test prints to fine-tune your settings for optimal results.

14. What’s the best print speed for small projects?

The ideal print speed for small projects with the Bambu Lab A1 Mini is typically between 40 to 60 mm/s. This speed balances quality and efficiency, producing detailed prints without compromising the final outcome. Adjust as needed based on the complexity of your design.

15. Can I print functional parts with the A1 Mini?

Yes, you can print functional parts with the Bambu Lab A1 Mini, especially using filaments like PETG or ASA. These materials offer greater strength and durability, making them suitable for parts that require functionality, such as brackets or gear components.

16. What maintenance does the A1 Mini require?

The Bambu Lab A1 Mini requires minimal maintenance. Regularly clean the print bed and nozzles, check for loose belts, and lubricate moving parts. Additionally, keep an eye on filament quality and storage to ensure consistent printing performance.

1. Is the Bambu Lab A1 Mini good for multi-color 3D printing?

Yes, the A1 Mini excels at multi-color printing when paired with the AMS Lite system. The combination allows for automatic filament switching during prints, enabling vibrant multi-color designs and functional color-coded components. The enclosed chamber design maintains consistent temperatures across different filament types, ensuring reliable layer adhesion in multi-material prints.

2. What filament types are compatible with the A1 Mini?

The A1 Mini supports a wide range of filaments including PLA, PETG, ABS, ASA, and TPU. PLA works best at 215°C with 60°C bed temperature, PETG requires 250°C nozzle and 80°C bed, while ABS needs 260°C nozzle temperature with 100°C heated bed. The enclosed chamber design particularly benefits temperature-sensitive materials like ABS by maintaining stable printing conditions.

3. How long do these projects typically take to print?

Print times vary significantly based on project complexity and settings. Simple projects like keychains or desk organizers take 2-4 hours, while complex assemblies like the mechanical clock or kinetic sculpture require 8-12 hours. Multi-part projects may need 15-20 hours total when accounting for all components, though they can often be printed in batches to optimize time efficiency.

4. Can I customize these designs before printing?

Absolutely! Most project files can be modified using standard 3D modeling software like Fusion 360, Tinkercad, or Blender. You can adjust dimensions, add personal engravings, modify mounting holes, or change aesthetic elements to match your specific needs. The modular nature of many designs makes customization particularly straightforward for storage systems and organizational components.

5. Do I need to calibrate the printer before printing these models?

The A1 Mini's automatic calibration system handles most setup requirements, including bed leveling and flow rate adjustment. However, for precision projects like measuring tools or tight-tolerance assemblies, manual verification of bed adhesion and first-layer quality is recommended. The machine typically maintains calibration across multiple prints, requiring intervention only when changing filament types or after extended use.

6. What is AMS Lite and how does it work with the A1 Mini?

AMS Lite is Bambu Lab's automatic material system that enables seamless multi-color and multi-material printing. It holds up to four filament spools and automatically switches between them during printing based on the sliced model requirements. The system works by retracting the current filament, loading the next specified material, and purging the nozzle to ensure clean color transitions, making complex multi-color projects achievable without manual intervention.

7. What makes the Bambu Lab A1 Mini ideal for beginners?

The Bambu Lab A1 Mini is perfect for beginners due to its user-friendly interface and compact design. It’s easy to set up and operate, offering features like automatic bed leveling and intuitive controls. The reliability of this 3D printer allows newcomers to focus on creativity without getting bogged down by complicated processes.

8. Which filament works best for these projects?

For most projects with the Bambu Lab A1 Mini, PLA filament is the best choice. It's easy to work with, offers excellent print quality, and is less prone to warping. Other filaments like PETG can also be used for functional parts, but beginners should start with PLA for a smoother experience.

9. How long does it take to print these models?

Print times with the Bambu Lab A1 Mini vary based on the model’s complexity and size. On average, small prints take between 30 minutes to a few hours. Larger or more intricate models can take several hours, so it's essential to optimize settings for efficiency without compromising quality.

10. Can I modify the 3D designs before printing?

Yes, you can easily modify 3D designs before printing with the Bambu Lab A1 Mini. Software such as Tinkercad or Blender allows you to alter STL files. Customizing designs lets you adjust sizes, shapes, or add personal touches, enhancing your printing experience.

11. Are these projects suitable for kids?

Absolutely! The Bambu Lab A1 Mini's easy controls and safety features make it suitable for kids, especially with adult supervision. Engaging in 3D printing can also enhance their creativity and problem-solving skills while introducing them to technology in a fun way.

12. Where can I download STL files for these projects?

You can find STL files for various projects on websites like Thingiverse and MyMiniFactory. These platforms offer a vast selection of designs, from toys to functional items, making it easy to start printing with your Bambu Lab A1 Mini.

13. How to ensure perfect prints with Bambu Lab A1 Mini?

To ensure perfect prints, start with a clean print bed and level it properly. Use high-quality filament and set the correct temperature settings for your material. Regularly check your printer's mechanical components and run test prints to fine-tune your settings for optimal results.

14. What’s the best print speed for small projects?

The ideal print speed for small projects with the Bambu Lab A1 Mini is typically between 40 to 60 mm/s. This speed balances quality and efficiency, producing detailed prints without compromising the final outcome. Adjust as needed based on the complexity of your design.

15. Can I print functional parts with the A1 Mini?

Yes, you can print functional parts with the Bambu Lab A1 Mini, especially using filaments like PETG or ASA. These materials offer greater strength and durability, making them suitable for parts that require functionality, such as brackets or gear components.

16. What maintenance does the A1 Mini require?

The Bambu Lab A1 Mini requires minimal maintenance. Regularly clean the print bed and nozzles, check for loose belts, and lubricate moving parts. Additionally, keep an eye on filament quality and storage to ensure consistent printing performance.