I like the product and how easy is it to use them and making a tight grip on the wires

for additional 5% discount! + Redeem RC COINS 👇

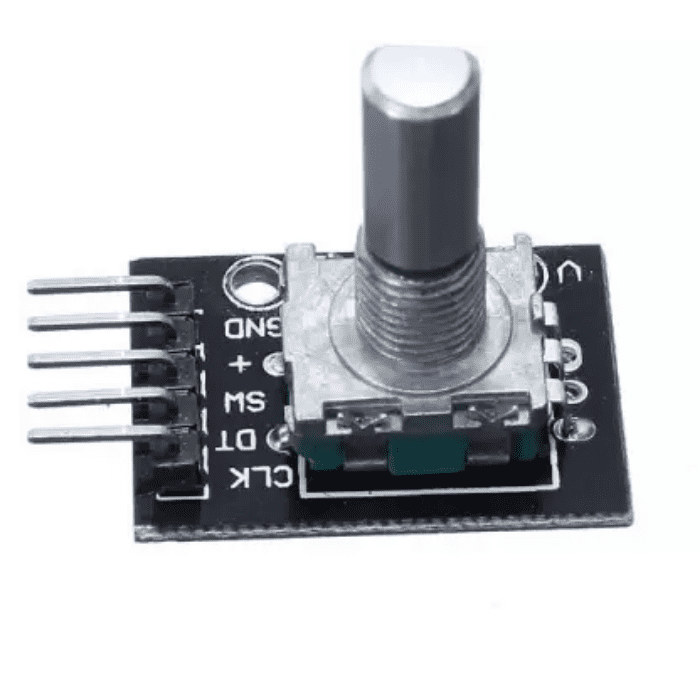

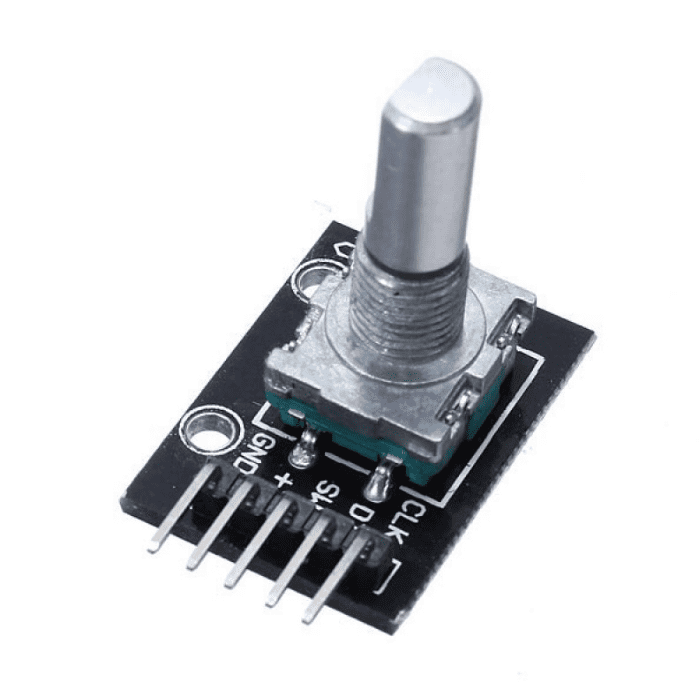

Rotary Encoder Module

Let us know!

We'll try to match the price for you

Couldn't load pickup availability

The Rotary Encoder Module Brick Sensor is a rotary input device (as in knob) that provides an indication of how much the knob has been rotated AND what direction it is rotating in. This Brick Sensor is a great device for stepper and servo motor control. You could also use it to control devices like digital potentiometers.

M274 360 rotary Degree encoder, is an incremental electro-mechanical device that converts the angular position or motion of a shaft or axle to digital code. The output of incremental encoders provides information about the motion of the shaft, which is typically further processed in processor/controllers into information such as speed, distance, and position.

read more : What are Rotary Encoders? Construction & Working

| Model | KY-040 |

| Cycles per revolution (CPR) | 20 |

| Working voltage | 0 – 5V |

| Material | PCB + Brass |

| Dimensions | 3 x 2 x 1cms |

| Weight | 25 grams |