I like the product and how easy is it to use them and making a tight grip on the wires

for additional 5% discount! + Redeem RC COINS 👇

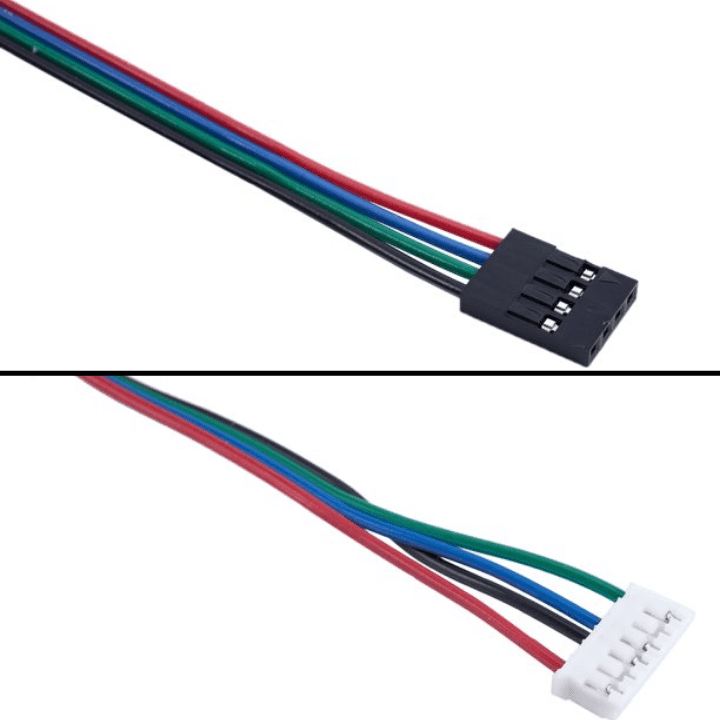

Pure Copper 720mm Length Cable with Dupont Connector for NEMA17 Stepper Motor

Let us know!

We'll try to match the price for you

Couldn't load pickup availability

This is Replacement cable for NEMA17 Stepper Motor. The conductors of this 720mm Cable with Connector for NEMA17 Stepper Motor consists of pure copper.

It has an overall length of 720 mm which is very convenient to install your stepper motor systematically in your projects or 3D printers etc. It equips 6 pin JST XH connector at one end and 4 pin Dupont connector at another end.

These are very flexible cables specially designed for connecting NEMA17 Stepper Motor with Stepper Motor Drivers.

| Material |

Pure Copper |

| Connector Type |

JST XH and Dupont |

| Length (mm) |

720 |

| Compatible with Motor Type |

NEMA17 |

Pure Copper

JST XH and Dupont

720

NEMA17