How to Troubleshoot Sensor Errors: Tips and Tricks

Summary

Sensors are everywhere in modern life. Your smartphone, your car, industrial robots, IoT devices, home automation systems all have sensors. When they work, you don't even notice them. But when they fail, everything comes crashing down.

Understanding sensor errors and knowing how to troubleshoot them can save you hours of frustration and potentially thousands of dollars in downtime. Let’s go through everything you need to know about identifying, fixing, and preventing sensor problems.

Common Types of Errors in Sensors

Before you can fix a problem, you need to understand what you're dealing with. Here are the most common types of errors in sensors you'll encounter:

- Overcurrent Failures: This is the number one killer of sensors. What happens is that even when you connect everything at the specified ratings, equipment startup creates inrush currents that spike way above normal operating values. These spikes fry the sensor's internal components, and suddenly your LED indicators stop lighting up or the sensor just refuses to conduct.

- Signal Degradation: This one's sneaky because it develops gradually. You start getting inaccurate readings, and when you investigate, you find cable disconnections, wire breaks, or damaged cable sheaths. In industrial environments, metal chips are the usual culprit—they tear through cable protection, coolant seeps in, and you get shorts and contact failures everywhere.

- Zero Offset Issues: Particularly common with pressure sensors and temperature sensor error situations. What happens is pressure gets trapped inside the sensor housing and can't fully dissipate. This creates measurement drift that throws off all your readings. Usually occurs when sealing rings deform under pressure or when someone overtightens the sensor during installation.

No Output Signal: The sensor gives you absolutely nothing. This points to:

- Power supply failures

- Incorrect wiring with reversed polarity

- Faulty electronic circuit boards

- Physical damage to sensing elements like diaphragms or strain gauges

Environmental Interference: Excessive temperature tops the list here as a leading cause of sensor fault diagnosis nightmares. Sensors exposed to fire or extreme heat develop all sorts of bias errors, and in severe cases, they're completely destroyed.

How to Identify a Faulty Sensor

To Identify a faulty sensor, you need a systematic sensor troubleshooting approach. Start with visual inspection for physical damage, burnt components, or loose connections on the sensor body and circuit board.

Check electrical connections by verifying proper power supply voltage, ensuring wiring is secure and correct, and testing for reversed polarity which prevents sensor operation. Use a multimeter to measure voltage and continuity across sensor terminals.

Perform benchmark tests before making adjustments. Compare sensor readings against a calibrated reference sensor to verify if the device requires adjustment or replacement. Monitor for erratic readings, fluctuating output, or complete signal loss during testing.

Examine environmental conditions including temperature variations, humidity levels, and electromagnetic interference that might affect sensor performance. A controlled environment often proves necessary for accurate diagnosis.

Review historical performance data and calibration records. Documentation of previous "as found" and "as left" measurements helps identify trends indicating progressive deterioration versus sudden failure.

How to Troubleshoot Sensor Errors

Now let me walk you through the actual troubleshooting process, because having a structured methodology makes all the difference between wasting hours on guesswork and quickly identifying the problem. Different kinds of sensors and their errors require different approaches to fix them. Below are some of these fixes.

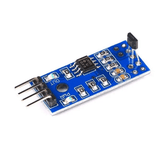

1. Understanding Hall Sensor Errors

Hall sensor error issues show up in several ways, and understanding these patterns helps you diagnose problems faster:

Common manifestations include:

- Erratic readings with inaccurate or fluctuating output

- Signal interference from external electromagnetic fields

- Mounting problems due to incorrect placement or misalignment

- Temperature sensitivity affecting performance

- Mechanical damage to sensor components

Now, let me explain something important about temperature effects on Hall sensors. Temperature fluctuations mess with these sensors through multiple mechanisms simultaneously.

Changes in carrier mobility within the semiconductor material, thermal expansion effects on sensor packaging, and variations in magnetic properties of nearby components all contribute to measurement errors in sensors.

Here's the scale we're talking about: these variations can lead to accuracy reductions up to 10% across typical industrial operating ranges of -40°C to 125°C. That's significant when you need precision measurements.

To troubleshoot hall sensor error issues effectively:

- Verify sensor placement and alignment relative to the magnetic field source

- Check for electromagnetic interference by shielding the sensor or relocating interfering equipment

- Assess sensor performance across temperature ranges to determine if compensation techniques are needed

- Watch for thermal time constant mismatches between the Hall element and temperature sensing components—these lead to transient sensor errors during rapid temperature changes

And here's my standard advice: always consult manufacturer datasheets and user manuals. Manufacturers include model-specific troubleshooting guidelines that address common sensor problems encountered with their specific products.

2. Fixing Proximity Sensor Errors

Proximity sensor error resolution starts with understanding how these sensors work. They detect objects without physical contact using electromagnetic fields, light, or sound. When they fail, you typically see detection failures, false triggering, or range inconsistencies.

Here's your troubleshooting checklist:

Clean the sensor face thoroughly. Dirt, dust, or debris blocks detection capabilities. I've seen expensive proximity sensors "fail" when all they needed was a good cleaning.

Verify detection range:

- Check that the sensor's range matches application requirements

- Ensure target objects fall within specified sensing distances

- Confirm no obstacles interfere with the detection path

Check alignment:

- Verify proper alignment between sensor and target objects

- Look for mounting hardware that's loosened over time

- Ensure no vibration or mechanical stress causes sensor movement

Examine target material properties. This is where a lot of people get stuck. Some proximity sensor error situations arise because target materials don't reflect or interact with the sensor's detection method appropriately. Metallic proximity sensors require conductive targets, while optical sensors need reflective surfaces.

Test the output signal using appropriate instruments:

- Verify voltage levels meet specifications

- Check current output if using current-loop sensors

- Confirm digital signals switch properly

- Replace the sensor if internal components show damage or degradation

3. Troubleshooting Temperature Sensor Errors

Temperature sensor error diagnosis requires understanding common failure modes. Let me break this down because temperature sensors fail in specific, predictable ways:

Common failure modes include:

- Zero offset: Trapped thermal energy prevents accurate readings

- No output: Complete circuit failures give you nothing

- Drift: Aging components gradually shift readings away from true values

For RTDs (Resistance Temperature Detectors) and thermocouples, wiring configuration is absolutely critical. Two-wire, three-wire, and four-wire RTD connections each have specific requirements. Get the wiring wrong and you introduce lead resistance errors in sensors that completely corrupt your readings.

Check for moisture ingress in sensor housings:

- Water contamination causes shorts

- Corrosion develops on terminals and circuit boards

- Erratic readings appear that seem random but actually track humidity

- Ensure sealing integrity and consider environmental protection upgrades for harsh conditions

Calibration for temperature sensors requires special attention:

- Calibrate against NIST-traceable reference thermometers

- Test at multiple temperature points across your operating range (don't just calibrate at one temperature)

- Document calibration curves and correction factors

- Keep detailed records for sensor maintenance tips

Here's something critical: review sensor placement carefully. I've seen countless cases where sensors positioned too close to heat sources like electronic components, motors, or direct sunlight gave completely skewed readings. Ensure adequate airflow around the sensor to prevent temperature gradients that create measurement bias.

And remember this: excessive temperature exposure remains the most common cause of complete sensor failure. Sensors caught in fires or subjected to temperatures beyond their ratings show various bias issues and may be destroyed completely. Always verify that your sensor selection matches application temperature extremes.

4. How to Resolve Magnetic Sensor Errors

Magnetic sensor error correction begins with proper calibration, and let me tell you, magnetic sensor calibration is more involved than most people realize.

Here's what you need to know about calibration requirements:

- Minimum 9 orientations: You need at least 9 significantly different orientations during calibration to achieve good precision

- Calibration types: Two types exist depending on your device's degrees of freedom

- Three-dimensional calibration: For devices that rotate freely in all directions

- Two-dimensional calibration: For devices with limited movement, but still provides good results for covered orientations

Environmental setup matters tremendously:

- Keep external magnetic disturbances at least 3 meters away during calibration

- Building structures containing steel create interference

- Computers, chairs, and desks all affect magnetic sensor error correction

- The calibration environment significantly impacts results quality

Common calibration failures include:

- Insufficient motion during the procedure (you need enough variety in orientations)

- Alignment issues from excessively fast movement (slow down!)

- Noisy magnetic field conditions from nearby equipment

- If you encounter errors, the fix is usually straightforward: slow down your movements, increase rotation variety, and improve environmental conditions.

For the technically minded, there are seven representative algorithms for in-situ calibration without special equipment. These algorithms correct dominant linear time-invariant measurement errors common in chip-form magnetometers embedded in larger systems. Algorithm selection depends on your accuracy requirements, computational resources, and deployment ease.

5. Dealing with Gravity Sensor Errors in Smartphones

Gravity sensor error in smartphones is incredibly frustrating because it affects so many functions—screen orientation, motion detection for gaming, fitness tracking, and all accelerometer-dependent applications. These sensors detect device orientation changes and signal when to switch between vertical and horizontal display modes.

Here's your step-by-step troubleshooting approach:

Start with a device reboot. I know it sounds almost too simple, but this resolves many temporary software glitches affecting sensor operation. The sensor systems get refreshed, and often that's all you need.

Access diagnostic testing modes:

- Many smartphones have built-in diagnostic codes

- Dial special codes to run gravity sensor tests

- These verify functionality and calibration status

- Built-in diagnostics help you identify hardware versus software issues

Check for software updates in system settings:

- Manufacturers release updates addressing sensor errors

- Updates improve calibration algorithms

- Firmware fixes often resolve persistent sensor issues

- Always install the latest available firmware

Here's something interesting about gravity sensors: some smartphones without gyroscopes show gravity sensor error because the gravity sensor relies on gyroscope data for certain calculations.

If physical rotations around the z-axis aren't detected while throw/move actions work fine, this indicates a sensor fusion limitation rather than true sensor failure.

Factory reset serves as your last resort:

- Use this when gravity sensor error persists after everything else

- System file corruption sometimes requires complete restoration

- Incorrect settings buried deep in the system might need clearing

- Always backup your data before factory resets

Common Sensor Calibration Issues and How to Fix Them

Sensor calibration issues arise from multiple sources, and understanding these helps you prevent problems before they start.

Common causes include:

- Environmental variations: Temperature and humidity during calibration significantly influence results, requiring controlled conditions

- Drift over time: All sensors drift gradually—it's just physics

- Improper procedures: Skipping steps or rushing through calibration introduces errors

Here's the foundation of good calibration practice: establish calibration standards linked to national or international measurement systems before making any adjustments. NIST-traceable references ensure calibration validity and traceability. Without proper standards, calibration introduces more errors in sensors than it corrects. I can't emphasize this enough.

Follow this calibration process:

Before calibration:

- Inspect and clean sensors

- Check for physical damage or contamination

- Confirm devices are fully functional

- Document current "as found" readings

During calibration:

- Use controlled environmental conditions

- Follow manufacturer procedures exactly

- Take measurements at multiple points across the operating range

- Make adjustments incrementally

After calibration:

- Document all activities including "as found" measurements, adjustments made, and "as left" readings

- Perform verification tests

- Evaluate calibration impact on process quality

Calibration scheduling prevents drift accumulation:

- Regular calibration catches developing problems early

- Frequency depends on sensor type, application criticality, and historical performance data

- Critical manufacturing sensors may need monthly calibration

- Stable environmental sensors might only need annual adjustment

When out-of-tolerance conditions occur, investigate root causes and implement corrective actions to prevent recurrence. This documentation proves essential for sensor fault diagnosis and quality assurance programs.

Develop systems for regularly reviewing and updating calibration procedures based on collected data, and incorporate calibration information into predictive sensor maintenance tips programs that anticipate failures before they occur.

Preventive Measures to Avoid Sensor Malfunctions

Preventing sensor errors proves more cost-effective than reactive troubleshooting. Implement comprehensive sensor maintenance tips including regular inspection schedules, environmental monitoring, and protective measures.

Design proper cable management systems ensuring bends exceed minimum bend radius specifications. Route cables away from chip-generating processes and provide physical protection against mechanical damage. Use appropriate strain relief at connection points to prevent wire breaks from vibration or movement.

Select sensors appropriate for the operating environment during initial system design. Many common sensor problems stem from choosing sensors without understanding available alternatives better suited to application requirements.

Consider temperature ranges, electromagnetic interference levels, vibration profiles, and contamination exposure when specifying sensors.

Install protective measures including filters for electrical noise, thermal barriers for high-temperature environments, and enclosures for corrosive atmospheres. These measures extend sensor life and reduce how to fix sensor malfunction incidents.

Train personnel on calibration best practices maintaining consistency across the organization. Educated staff recognize early warning signs of sensor deterioration and implement corrections before complete failure occurs.

Regular training updates keep teams current with evolving sensor technologies and troubleshooting sensors methodologies.

Develop predictive maintenance programs incorporating sensor calibration data, performance trends, and failure history. Analytical approaches identify patterns indicating impending failures allowing scheduled replacement during planned downtime rather than emergency repairs.

Conclusion

Mastering sensor troubleshooting requires understanding common failure modes, systematic diagnostic approaches, and preventive strategies. Whether you're dealing with an error occurred with the fingerprint sensor, proximity sensor error, or magnetic sensor error, the principles remain consistent: verify the basics first, use proper tools, document everything thoroughly, and implement preventive measures.

With these tips and tricks in your toolkit, you can maintain sensor reliability and quickly resolve issues when they arise, saving time, money, and frustration.