NEMA 17 Mounting L Bracket for Stepper Motor for 3d printer

Original Arduino UNO EK (एक) R4 Minima - Made in India

0.96 Inch OLED Display Module SPI/I2C 4pin Blue Color

F450 4-axis Quadcopter Drone Frame Kit with Integrated PCB (Black & White)

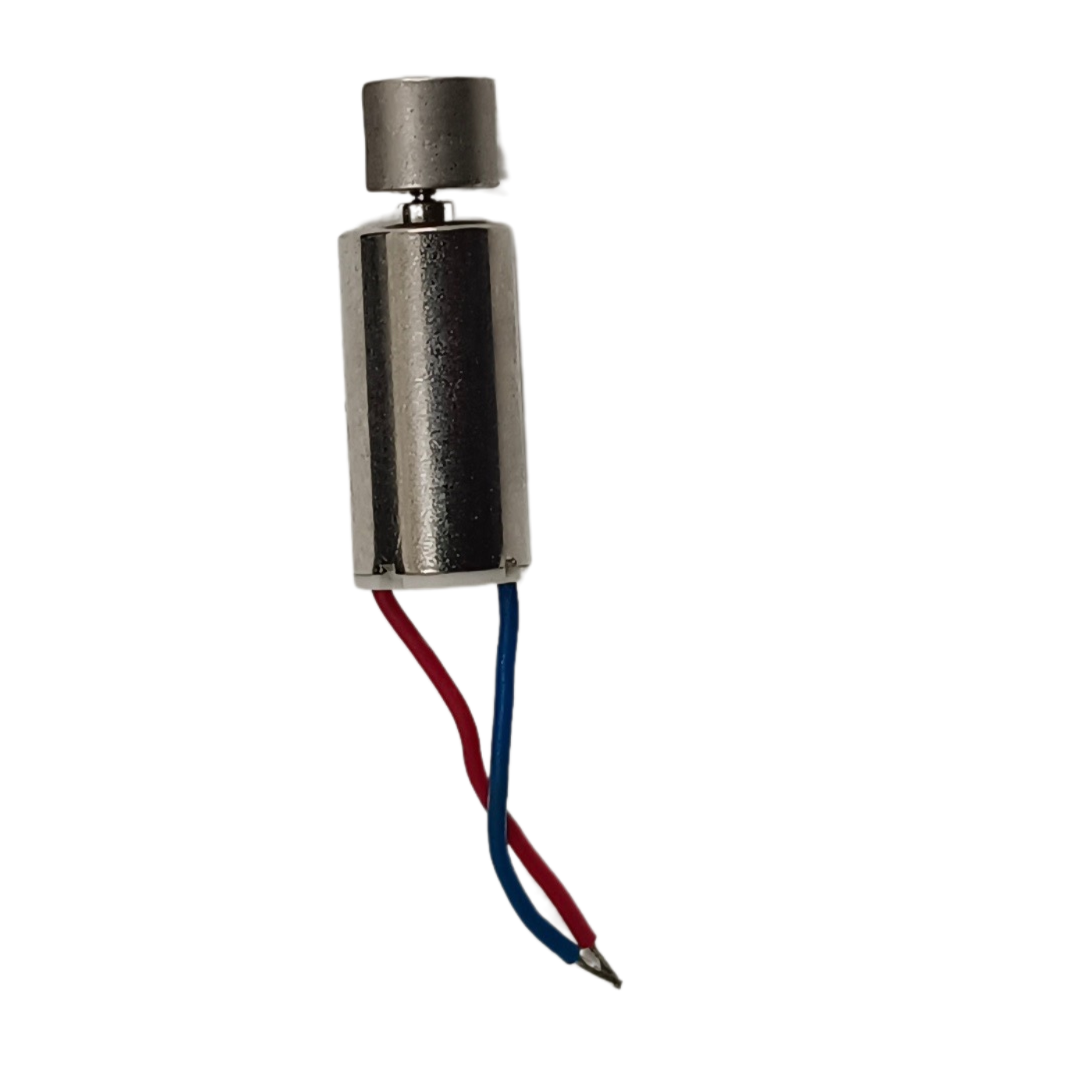

Micro Vibration Motor

Let us know!

We'll try to match the price for you

We’ll notify you once the product is back in stock.

Couldn't load pickup availability

Micro vibration motors are small, high-torque motors that are designed to produce vibration. They are commonly used in a wide range of applications, including mobile devices, gaming controllers, and other electronic devices that require vibration feedback.

Micro vibration motors typically have a diameter of a few millimeters to a few centimeters and can be driven by a DC voltage or current. They are usually designed to operate at low voltage and current levels, and are often controlled using pulse-width modulation (PWM) techniques to adjust the intensity of the vibration.

Micro-vibration motors are widely available from a variety of manufacturers and distributors, and can be purchased online or from electronics stores. They are relatively inexpensive and are commonly used in a wide range of electronic projects and applications.

Also check Vibration Motor available on the ROBOCRAZE website. It is a small-sized motor made from Toy Motor, designed for high stability and quick assembly. The motor operates within a voltage range of 4.5V to 6V, with a nominal operating voltage of 5V. It is known for its stable performance, high-temperature resistance, and long service time.

| Dimensions (l x w x h) | 17 x 6 x 6 mm |

| Weight | 5g |