5 diy projects using servo motors

Summary

Discover the world of servo motors with these 5 captivating DIY projects! From a dual servo dance choreographed by a joystick to an automatic door powered by servo motors, this blog dives into the realm of robotics and automation. Explore crafting a cinematic gimbal, building a DIY pan-tilt camera control, and even assembling a futuristic robotic arm. Unleash your creativity and technical skills while embracing the possibilities of servo motor technology. Ready to bring your ideas to life? Let's get started on these exciting ventures into the world of robotics!

Introduction:

The do-it-yourself projects world is a path to infinite potential often sparked by ingenuity and new findings. A globally used tool that is used to develop technology and help in advancements is at the heart of this ongoing journey. It is a powerful device which is crucial due to its versatile and precise nature. we will be guided through 5 remarkable creations involving servo motors in this blog. The blog will feature multiple projects, starting from beginner level to advance projects so, whether you are taking your first step towards your DIY ride or are a seasoned maker seeking new challenges, these projects will inspire and empower you. With the power to choose between an Arduino or a Raspberry Pi, let us dive into servo motor-driven creations.

Understanding servo motors:

A servo motor is a combination of mechanics and electronics which is designed to transform electrical energy into precise mechanical motion. This is orchestrated by a trio of components – a motor, a gearbox, and a feedback control system. The motor generates torque to move the shaft, while the gearbox transforms high-speed rotation into motion. What truly sets servo motors apart is their closed-loop control system, consisting of a potentiometer or encoder. The position in which the shaft is present is monitored throughout by the system, it gives the feedback of this to the controller for proper control of the angle. A combination of these provides us very important features that can be vital for some makers where it calls for such benefits

Project 1: Joystick-Guided Dual Servo Dance

Project description:

Get ready to witness the fusion of technology and artistry in the dual servo dance project, guided by the joystick. As you navigate the joystick, two servo motors respond with precise motion, translating our directional cues into a dance. each twist and turn transform the project into a vibrant canvas. The symphony between command and imagination, enables us to control the graceful duet of the servos. This project is a beginner-friendly project, it is easy to use and create therefore making it the best starting point for this journey.

Components Required:

Also, read our blog on the Smart Dustbin Project explaining everything from what hardware is required, how it works, pin diagram, and the Arduino code.

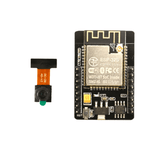

Project 2: ESP32 Cam Vision Shift using DIY Pan Tilt Control:

Project Description:

Dive into the DIY Pan Tilt Control and elevate our photography and videography skills. There is no one that does not like to see from a fresh perspective. Thanks to the ability to move around our environment in a flexible way, we can now capture images from fresh perspectives and convey narratives in a completely innovative manner. The integration of servo motors enables remote adjustment of your ESP32 Cam's orientation. This fun project will truly fascinate users as it is easy to create using the pan and tilt kit or we can even 3d print parts to do this Whether it is landscape or portrait shots this project will elevate the ability to shoot footage or pictures.

Components Required:

- ESP32 Cam

- Servo motors (2)

- Pan Tilt bracket

- Arduino or Raspberry Pi

- Jumper wires.

Project 3: Crafting Cinematic Stability: DIY Gimbal with Arduino and MPU6050:

Project Description:

We present to you the DIY gimbal project, a gateway to cinematic stability. Using the Arduino and the MPU6050 sensor to create a stabilizer for cameras and smartphones. Signals are transmitted to the servo motors by the sensor, allowing the camera's position to be adjusted and shaking to be eliminated by detecting any changes in the orientation. capturing any type of footage or action sequences, this project will help us in getting steadiness.

Components Required:

- Arduino board

- MPU6050 sensor

- Servo motor

- 3D-printed gimbal parts

- Power supply

- Jumper wires

Project 4: Embrace Automation: Building an Automatic Door with Servo Motors:

Project description:

Merge technology and convenience with the automatic door project. Enable servo motors to engineer a door-opening mechanism that springs to life upon motion detection. The servo motor gives smooth movement providing a smooth entry experience. Elevate home automation or enhance living spaces with futuristic interactions.

Components Required:

- Servo motor

- Motion sensor

- Door Mechanism

- Arduino or Raspberry Pi

- Power supply

- Jumper wires

Project 5: Unveil the Future: Crafting a Robotic Arm with Servo Motors:

Project Description:

In the field of robotics, this project unveils a robotic arm. Assemble servo motors and the parts to bring the arm to life, mimicking human-like motions. By controlling servo angles we can guide the arm to grasp, move, and manipulate objects. This futuristic creation will help young minds the ability to think deeply and discover amazing things that can be implemented in our lives.

Components Required:

- Servo motors (multiple)

- Robotic arm kit or 3D-printed parts

- Arduino or Raspberry Pi

- Power supply

- Jumper wires

Conclusion:

This blog takes us through these five mesmerizing DIY projects. The versatility of servo motors is seen brilliantly. From precise control to cinematic artistry, from automation to robotics, servo motors infuse life into your creative endeavors. With this, we can redefine innovation's boundaries. Embrace servo motor magic, nurture your ideas, and witness your DIY dreams metamorphose into reality. Your maker journey is unbounded, and the wonders you can craft, limitless.

If you appreciate our work don't forget to share this post and leave your opinion in the comment box.

Please do check out other blog posts about Popular electronics

Make sure you check out our wide range of products and collections (we offer some exciting deals!)