Drone Motor Maintenance: Tips to Keep Your Motors Running

Summary

In the world of drones, motor maintenance is often overlooked but essential for peak performance. In our comprehensive blog, we delve into the intricacies of drone motors. Starting with an introduction to their importance, we explore the signs of motor problems that every drone pilot should watch for. Discover effective maintenance procedures to extend your motor's lifespan and expert tips on managing motor temperatures. We'll also share preventative maintenance strategies to avoid costly repairs and delve into troubleshooting and repair when issues arise. Don't miss our conclusion for a summary of key takeaways. Keep your drone flying high with these essential tips!

Introduction

Maintaining your DIY drone motor is of the utmost importance to maximize its performance and ensure safety for flying. Routine maintenance should be regularly scheduled, as it can help identify any areas that require attention before they become larger problems down the line. Checking bolts, screws, nuts and other fasteners are essential so they don't come undone during flight due to vibration or turbulence; replacing worn-out parts such as propellers or motors when appropriate will also help save significant costs in future repairs or upgrades. Additionally, proper lubrication of gears helps keep them functioning correctly while avoiding premature wear allowing longer life cycle cost savings over time. All these routine checks pay off by ensuring a smooth operation with your vehicle each and every time you take it out!

Well-maintained motors play a critical role in the performance and longevity of drones. The quality of these components can determine how well your drone operates, including its speed, acceleration, manoeuvrability, battery life and more. By routinely inspecting motor wear for signs such as corrosion or discoloration and replacing faulty parts before they become dangerous to use can ensure that you're getting optimal flight time from each charge. Additionally investing in high-quality builds with durable materials designed specifically for indoor or outdoor flying will drastically reduce maintenance costs over time while also ensuring all necessary repairs are completed quickly when needed. When it comes to keeping any type of air vehicle performing at its best - reliable motors maintained using only manufacturer-approved techniques is absolutely essential!

Understanding Drone Motors

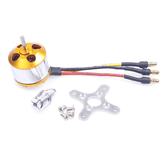

Drone motors are essential components that work together to power the flight of a drone. Motors come in different styles, depending on their use and application. There is Brushless DC Motor, Coreless Motor, Outrunner motor and Inrunners motor which all offer distinct benefits for powering drones or other remote-controlled aircraft. Brushless DC Motors provide high efficiency with low noise levels while coreless motors typically have small size and lightweight advantages as they do not need iron cores like brush types do. Outrunner models also operate more efficiently but usually require bigger rotors since they spin outside the main body of their enclosure unlike an inner rotor variant (Inrunner). All these variations provide creative minds with infinite possibilities when it comes to constructing custom DIY projects powered by efficient motion solutions!

Motors are the key driving force behind DIY drone operations. Without these miniature dynamos, a drone would simply be an empty shell with no capability to fly or perform any action associated with it. Motors provide thrust that propels drones into the air and guides them along their trajectory using propellers attached directly to each motor shaft. Furthermore, motors allow for incredible maneuverability around obstacles due its low mass weight-to-power ratio as well as efficient current consumption which helps prolong flight time significantly compared to normal RC aircraft of similar size and shape without sacrificing efficiency; allowing more complex missions than ever before in areas such aviation photography, cargo delivery etc. All of this makes DIY motors vital components when creating your own custom-built aerial vehicle achieving maximum performance from minimal resources making it all possible at home!

read more : Working of A Drone

Signs of Drone Motor Problems

Signs of Drone motor problems can be difficult to detect but often manifest in a few distinct ways. Common symptoms include short flight times, poor acceleration or an overall lack of power when flying. If your drones’ motors aren't running smoothly and efficiently, you may also hear uncharacteristic noises such as buzzing, grinding or clicking coming from the rotors and/or shafts. Additionally, if you've noticed that your craft has been vibrating more than usual while in flight - particularly during quick manoeuvres - this could indicate some underlying issues with its motors too. It is important to note that all these signs don't necessarily imply there's something wrong; however, they should be checked out just in case as leaving things unchecked can lead to further damage down the line.

read more : Drone Motor – Where to Begin?

Visit our Drone Motors collection page for powerful Motors.

Drone Motor Maintenance Procedures

Maintaining the motors of your Drone is an important step in making sure it stays operational. To ensure peak performance, ensuring that all internal components are clean and free from debris buildup, along with regularly lubricating any moving parts should be done frequently. Additionally, inspect the motor couplings for signs of wear or damage and replace as necessary to keep everything securely together. Lastly, take time to check for loose screws on both the exterior casing and interior insulation wiring connections before taking flight each time to avoid any potential issues while airborne! Make a routine out of these maintenance steps so you can enjoy years' worth of quality flying experiences with your DIY drone!

read more : How to choose ESC for Quadcopter

Drone Motor Temperature Management

As the popularity of drones continues to grow, it is important that users understand proper temperature management for their motors. Drone motor temperature management ensures your high-powered engines don't overheat and are able to withstand intense conditions while you fly. It can also increase performance, extending flight times and maximizing enjoyment with every adventure. Managing temperatures on your own requires access to thermometers or engine monitoring systems as well as a few other tools including heat sinks or fans if needed – all simple additions when building out any custom craft! Proper maintenance will help ensure years of reliable service from your build without costly repairs caused by improper care - making DIY drone motor temperature management an essential part of any safe flying environment.

read more : Best flight controller for drone

Drone Motor Preventative Maintenance

Drones are becoming an increasingly popular hobby, and motor preventative maintenance is essential for keeping them in peak condition. Drone motor maintenance can not only save you time and money but also extend the longevity of your drone's motors. By regularly checking each component of the system - including batteries, wires, and connections - it eliminates potential issues before flights occur. Additionally, regular cleaning will help remove any dirt or dust particles that may interfere with performance as well as reduce noise levels during operation. Professional grade lubrication should be utilized on all moving parts to ensure efficient movement without putting too much strain on the components themselves resulting in more reliable drones over longer periods of usage. Investing some effort into proper preventive maintenance now could avoid future problems down the road making sure your flying experience remains enjoyable long-term!

read more : Choosing the right propellers for your Drone

Drone Motor Repair and Troubleshooting

Repairing and troubleshooting drones can be challenging, but with the right guidance, anyone can do it. At Drone Motor Repair & Troubleshooting we have a team of professional technicians to help you get your drone off the ground safely. We provide comprehensive maintenance, repair and tuning services for all types of motors used in amateur radio-controlled aircraft. Our experts will inspect every component thoroughly before making repairs or recommending replacement parts as needed; from motor replacement to rewiring harnesses our experienced staff is equipped to handle any situation! With over ten years serving this industry, we guarantee quality work at competitive prices so that you can fly worry-free!

read more : Drone transmitter and receiver guide

Conclusion:

Ensuring the longevity and optimal performance of your drone motors is essential for every drone enthusiast. From understanding the intricacies of drone motors to recognizing signs of trouble and implementing effective maintenance procedures, we've covered it all. Remember to keep a close eye on motor temperatures and prioritize preventative maintenance to avoid costly repairs. And when issues do arise, don't panic – armed with troubleshooting knowledge, you can often get your motors back in top shape. By following these tips, you'll not only extend the lifespan of your drone motors but also elevate your aerial adventures to new heights. Click now to explore more drone maintenance insights and soar with confidence!

If you appreciate our work don't forget to share this post and leave your opinion in the comment box.

Please do check out other blog posts about Popular electronics

Make sure you check out our wide range of products and collections (we offer some exciting deals!)