Gas Sensor Types & Working

Summary

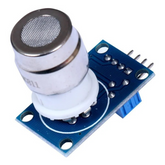

Discover the fascinating world of gas sensors in our latest blog! In this informative and engaging piece, we delve into the essentials of gas sensors, exploring their purpose, detection capabilities, and types. Learn how these remarkable devices work, enabling us to detect various gases and ensure safety in diverse environments. Dive into the testing methods used to validate their accuracy, and get insights into the cost considerations of gas sensors. Discover why gas sensors are crucial in today's world and how they contribute to our well-being. Finally, we explore the lifespan of gas sensors, shedding light on their durability and long-term effectiveness. Join us and unravel the mysteries behind this vital technology!

What is a gas sensor?

A gas sensor is an apparatus designed to identify the existence of diverse gases in the surroundings. These detectors have extensive usage, ranging from industrial locations to personal electronic devices. Their exceptional sensitivity, precision, and consistency make them an indispensable instrument for ensuring safety and safeguarding the environment.

What does it detect?

Different gases such as carbon monoxide, methane, propane, and volatile organic compounds can be detected by gas sensor. The capacity of a sensor to detect a specific gas depends on the type of sensor and the underlying technology.

Types of gas sensors

There are several types of gas sensors, each with its own unique characteristics and capabilities. Some of the most common types include:

- Metal oxide semiconductor (MOS) sensors: These sensors use a metal oxide layer to detect gases. They are highly sensitive and can detect a wide range of gases.

- Electrochemical sensors: These sensors use an electrochemical reaction to detect gases. They are highly accurate and can detect low levels of gases.

- Infrared sensors: These sensors use infrared light to detect gases. They are highly sensitive and can detect a wide range of gases.

How does gas sensing work?

Typically, these sensors operate by transforming the chemical energy of the gas into an electrical signal that is quantifiable and can be utilized to establish the gas concentration.

The chemiresister's capacity to conduct current determines a gas sensor's ability to detect gases. Tin Dioxide (SnO2), an n-type semiconductor with free electrons, is the type of chemical resistor that is most frequently utilized. Typically, flammable gases will be outnumbered by oxygen in the atmosphere. The free electrons in SnO2 are drawn to the oxygen particles, pushing them to the SnO2's surface. The output current will be nil since there are no available free electrons. The oxygen molecules (blue) in the SnO2 are drawing free electrons (black) there, as seen in the gif below, keeping it from being able to conduct electricity.

This Toxic gas (orange in color) reacts with the adsorbed oxygen particles and breaks the chemical connection between oxygen and free electrons, releasing the free electrons when the sensor is exposed to hazardous or flammable gases. The free electrons, having returned to their original positions, are now able to carry electrical current. The amount of current that can be carried depends on the number of free electrons available in SnO2. In case the gas is highly toxic, there will be a greater number of free electrons.

How do you test a gas sensor?

Let us consider the MQ2 gas sensor as a reference and see the connections from the sensor to Arduino

Connect Vcc to 5V, GND to the ground of Arduino. Connect the AOUT terminal to any analog pin in Arduino.

Here, we test the working of the sensor by receiving data from the AOUT terminal, the value that we receive from the sensor determines the toxicity of the gas, when the value is higher indicates the smoke level in the atmosphere is higher, and vice-versa.

The usage of DOUT terminal is simple, as when we get a high signal from that terminal that indicates the threshold for toxic gas levels is crossed.

What is the cost of gas sensor?

The price of gas sensors fluctuates based on the sensor type and its intended usage. A few sensors may be inexpensive, costing roughly ₹ 100 to 200 INR, while others can be costly, costing approximately ₹ 2000 to 3000 INR. When choosing a gas sensor, it's crucial to assess your application's particular needs and pick a sensor that satisfies those requirements while also taking cost into account.

Why gas sensors are needed?

Gas sensors are needed in many different applications to ensure safety and protect the environment. Some of the key reasons for the need for gas sensors include:

- Air quality monitoring: Gas sensors are used to measure the concentration of pollutants and other harmful gases in the air. This can be important for monitoring air quality in industrial areas, as well as in cities and other populated areas.

- Safety in industrial settings: Gas sensors are used to detect potentially dangerous levels of gases in industrial settings such as oil and gas refineries, chemical plants, and other industrial facilities. This can help to prevent accidents and protect workers from exposure to harmful gases.

- Leak detection: Gas sensors can be used to detect leaks of gases such as methane and propane in pipelines, storage tanks, and other industrial equipment. This can help to prevent explosions and other accidents.

- Consumer safety: Gas sensors are used in consumer devices such as home appliances and personal safety devices to detect potentially dangerous levels of gases such as carbon monoxide, and LPG. This can help to prevent accidents and protect families from exposure to harmful gases.

- Environmental monitoring: Gas sensors can be used to monitor the concentration of gases in the atmosphere, such as methane, carbon monoxide, and other greenhouse gases. This can help to track the impact of human activities on the environment and to make informed decisions about reducing emissions.

How long do gas sensors last?

The operational life of electrochemical sensors for common gases like carbon monoxide or hydrogen sulphide is commonly quoted at 2 to 3 years. The lifespan of more rare gas sensors, like those for hydrogen fluoride, may only be 12 to 18 months. Electrochemical sensors have been reported to run for more than 11 years under perfect circumstances, with stable temperatures and humidity with no occurrence of pollutants. The lifespan of these tiny fuel cells is unaffected by repeated exposure to the target gas because high-quality sensors feature substantial amounts of catalyst material and durable conductors that are not exhausted by the reaction.

Conclusion

Gas sensors play a vital role in detecting different gases present in the environment. These devices find their applications in various fields and can exhibit high sensitivity, accuracy, and dependability. By selecting the appropriate type of sensor and performing adequate testing and upkeep, you can ensure the longevity of your gas sensor for several years.

If you appreciate our work don't forget to share this post and leave your opinion in the comment box.

Please do check out other blog posts about Popular electronics

Make sure you check out our wide range of products and collections (we offer some exciting deals!)