Gear Motors: The Ultimate guide

Summary

Looking for a powerful and efficient motor for your machinery? Look no further than gear motors! These motors combine a traditional electric motor with a gearbox to provide torque, speed reduction, and directional control.

They're used in a variety of industries, from manufacturing to automotive to robotics. In this blog, we'll explore the differences between gear and non-gear motors, how they operate, the various types of gear motors with examples, and their advantages and costs.

Whether you're a DIY enthusiast or an industrial engineer, gear motors are a versatile and valuable tool to have in your arsenal.

This blog post aims to cover the fundamentals of gear motors, including their definition, applications, advantages, distinctions from non-gear motors, working principles, and different types.

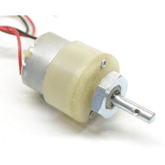

What are Gear Motors?

Gear motors are electric motors that have a gearbox attached to them. By multiplying the torque output of the motor, the gearbox enables it to deliver greater power while operating at a reduced speed.

Where are they used?

Gear motors are used in a wide range of applications such as:

- Conveyor systems, automatic doors, and other industrial equipment

- Robotics and automation

- Electric vehicles

- Home appliances like washing machines and refrigerators

- Medical equipment

- Automatic gate openers

- Automatic vending machines

Why are they used?

Gear motors are used because they provide precise control of speed and torque. The gear reducer is typically designed to increase the output torque while retaining a compact size, without increasing the motor's power consumption.

The cost of torque multiplication is a corresponding decrease in output shaft speed and a loss of overall efficiency. The best output and speed profiles can be attained, together with the ideal mechanical fit, by using the appropriate gear technology and ratio for certain applications.

Difference between Gear & Non-Gear Motor

A gearbox distinguishes a gear motor from a non-gear motor. In particular, a gear motor refers to an electric motor that comes with an attached gearbox, whereas a non-gear motor lacks this feature.

The gearbox functions as a mechanical apparatus that modifies the motor's speed and torque. It achieves this by leveraging gears to amplify the motor's torque output, empowering it to generate more power at a slower pace. Such capability proves beneficial when the motor is tasked with lifting heavy objects or covering long distances.

Non-gear motors, on the other hand, provide power directly to the load. They are typically less efficient than gear motors because they lose power as heat. They also have a limited torque output, which means they can't handle heavy loads. Non-gear motors are typically smaller and simpler in design, and thus less expensive.

Another difference is that gear motors are more precise in terms of speed control. The gearbox allows the motor to provide power at a slower speed, which allows for precise speed adjustments. Non-gear motors are typically more difficult to control and are often limited to simple on-off switching.

How do Gear Motors Operate?

Gear motors utilize electric motors that rotate a gearbox with a series of gears. Each respective pair is responsible for slowing down speed while doing the gear motor's power provision work. This results in gear motors providing powerful, controlled movement for an infinite number of different applications.

Types of Gear Motors with Examples

There are several types of gear motors available, each with their own unique features and characteristics. Some of the most common types include:

Helical Gear Motor:

It is a type of gear motor that uses helical gears to reduce the speed and increase the torque output of the motor. It is commonly used in electric vehicles, home appliances, and medical equipment. It is known for its high efficiency, low noise, and smooth operation.

Bevel Gear Motor:

It is a type of gear motor that uses bevel gears to change the direction of rotation of the motor. It is commonly used in automatic gate openers, industrial equipment, and other applications where the direction of rotation needs to be changed. It is known for its high torque output and its ability to change the direction of rotation.

Spur Gear Motor:

It is a type of gear motor that uses spur gears to reduce the speed and increase the torque output of the motor. It is commonly used in low-power, low-speed applications such as small appliances and toys. It is known for its simplicity and low-cost.

Inline Helical Gear Motor:

It is a type of gear motor that uses an inline helical gearbox to reduce the speed and increase the torque output of the motor. It is commonly used in conveyors, pumps, and other industrial equipment. It is known for its high efficiency, high torque density, and low noise.

Advantages & Cost of Gear Motor

Gear motors offer several advantages over non-gear motors including:

- Increased torque output: Gear motors can handle heavier loads than non-gear motors because the gearbox multiplies the torque output of the motor.

- Precise speed control: Gear motors can provide precise speed control because the gearbox allows the motor to provide power at a slower speed.

- Longer lifespan: Due to the mechanical advantage provided by the gears in the gearbox, gear motors experience less wear and tear, resulting in a longer lifespan when compared to non-gear motors.

As for the cost, gear motors are typically more expensive than non-gear motors because they have additional components like gearbox. However, the added cost is typically offset by the increased efficiency and lifespan of gear motors.

Conclusion

Gear motors combine an electric motor with a gearbox to deliver mechanical power and are utilized in various applications that necessitate accurate regulation of speed and torque. They tend to be more efficient and have a greater lifespan than non-gear motors, albeit at a higher cost. Selecting between a gear motor and a non-gear motor will hinge on the specific needs of the application.

If you appreciate our work don't forget to share this post and leave your opinion in the comment box.

Please do check out other blog posts about Popular Electronics

Make sure you check out our wide range of products and collections (we offer some exciting deals!)