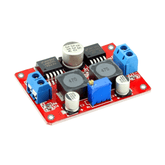

Buck-Boost Converter: What is it?

Summary

Discover the power behind a Buck-Boost Converter in our latest blog! Uncover the basics with an insightful introduction, demystify its workings, and explore the key benefits and applications that make it an engineering marvel. Delve into its variants and enhancements for a comprehensive understanding. Whether you're a tech enthusiast or an industry professional, this blog is your gateway to mastering the Buck-Boost Converter. Don't miss out on the electrifying insights – read on and boost your knowledge!

Introduction

Buck-boost converters are a type of switched-mode DC-to-DC converter that have gained immense popularity in power electronics due to their unique capability - they can output a voltage that is either lower or higher than the input voltage supplied. This flexible conversion ratio enables buck-boost regulators to produce multiple steady voltage rails from a single input, regardless of fluctuations across that input.

These converters work by temporarily storing input energy in an inductor's magnetic field during the switch-on phase and then releasing that stored power to the output during the switch-off phase. By modulating the switch duty cycle, the output voltage can be precisely controlled to a desired level. This lets buck-boosts maintain regulated outputs across varying inputs, from sources like batteries which experience substantial voltage changes during discharge.

The ability to step-up or step-down voltages with high efficiency makes buck-boost converters extremely useful as voltage regulators in low voltage, battery-operated devices. They allow extraction of the maximum amount of energy from the source before it is fully depleted. The regulated outputs can cleanly power sensitive analog and digital electronics. Versus linear regulators, buck-boost switching regulators waste much less energy as heat during the conversion process.

What is a Buck-Boost Converter?

In essence, a buck-boost converter is a switch-mode DC-to-DC transistor/switch regulator that can take an input voltage and convert it to an output voltage that is lower or higher than the input. This is achieved through the interaction of four key components - an inductor, a high frequency transistor/switch, a diode, and an output capacitor. These parts are interconnected in a specific inverted polarity configuration which enables voltage conversion in either direction.

By rapidly turning the switch on and off, the input voltage is pulsatingly applied to the inductor during the switch ‘on’ time. This causes current to build up and energy to be stored in the inductor’s magnetic field. When the switch turns off, the only path for the current is through the diode onto the output capacitor and electronic load. This discharges the inductor’s stored energy into the output side.

The ratio of switch on-time to off-time is critical and is called the duty cycle. By precisely varying duty cycle using pulse-width modulation, the output voltage can be controlled to a desired value below or above the input rail. This control allows the synthesis of multiple outputs from a single input.

Buck converters generate an output voltage lower than their supply voltage, while boost converters generate higher voltages. Buck-boost converters exhibit both capabilities through careful manipulation of duty cycle. Their output flexibility makes feasible regulation of voltage rails powered from unstable sources. For example, wide input lithium batteries vary from 4.2V when fully charged down to 2.5V when nearly depleted. Still, buck-boosts could take this fluctuating input and generate steady 3.3V, 5V and 12V outputs.

How a Buck-Boost Converter Works

The basic operating principles of a buck-boost converter involve controlling the path of current flow through the inductor to transfer packets of charge from input to output based on switching states. Let’s walk through the sequence of events during converter operation:

In steady state when the high frequency switch is activated, the input voltage source is applied directly across the inductor. Because inductors resist changes in current, this causes the inductor current to ramp up linearly. Energy is stored in the inductor’s magnetic field during this phase. Current flow is from the input source, through the switch and inductor.

When the PWM controller turns the switch off, current must continue flowing in the inductor because it cannot change instantly. The only path is now through the diode onto the output capacitor and electronic load. This transfers the inductor’s stored energy to the output side. The capacitor smooths the pulsed output into a stable DC voltage.

By toggling the switch rapidly using pulse width modulation (PWM), packets of charge are transferred from input to output through the inductor. If the switch on-time is short compared to the off-time, the output voltage must be lower than the input rail - a buck converter. If instead the on-time dominates, then the output will be higher than the input - creating a boost. Buck-boost converters synthesizes both scenarios.

Buck-boost converters generally operate in either continuous or discontinuous conduction mode. In continuous conduction, the inductor always has current flow even during the switch off-time. This generally provides more stable output voltage and efficiency at high loads. In discontinuous mode, the inductor current falls to zero for a portion of the cycle. This often occurs at low load currents. Switching between modes can enable optimizing efficiency across various conditions.

For example, say a 12V input should create a 24V output for a 50% duty cycle. When the switch closes, 12V appears across the inductor for 50% of the time. This energy transfers to the output side when the switch opens during the other 50%. The output capacitor now sees 2X the input voltage during this phase, generating 24V out. The inverted buck-boost topology enables this boost conversion.

Key Benefits and Applications

Buck-boost DC/DC converters provide several major advantages that explain their popularity in electronics:

- Wide Output Voltage Range: By synthesizing waveforms with varying duty cycles, the output voltage can be precisely adjusted anywhere below or above the input rail. This allows configuring buck-boost converters for vastly different applications without hardware changes.

- High Efficiency: Utilizing FET switching and low loss components, efficiencies of 90-95% are achievable. This prevents wasted energy and heat generation, enabling use in sensitive battery-powered devices. Light load efficiency can also be optimized.

- Regulated Output: Switching regulation generates steady output voltages despite input fluctuations or load changes. This clean power can cleanly run sensitive analog and digital electronics without stability concerns.

Given these benefits, buck-boost converters find use in a diverse set of applications including:

- Battery-powered Electronics – Wearables, sensors, monitors, IoT devices leverage minimal energy use for long run times.

- Transportation – Electric vehicles, hybrids, spacecraft, satellites all have fluctuating supply voltages where regulation is critical.

- LED Drivers – High voltage inputs can convert down to lower, constant voltage LED arrays efficiently.

- Voltage Regulation – Steady voltage generation for noise sensitive components despite variable inputs.

- Power Amplification – Low level inputs can convert to higher voltages to drive amplification stages.

- Renewable Energy – Solar/wind power fluctuations can become regulated outputs.

Variants and Enhancements

While the standard buck-boost topology described covers many use cases, some applications benefit from specialized enhancements:

- Inverting vs Non-Inverting: Buck-boost output polarity can be inverted to obtain either a positive or negative rail from the same input supply. This involves rearrangement of diode and switch placement in the core topology.

- Higher Current: To handle high load currents, specially selected FETs, diodes, inductors and capacitors handle greater power dissipation without losses. Multi-phase designs also distribute stresses.

- Control Circuits: Integrated circuits including PWM controllers, FET drivers, compensation, voltage/current protections are commonly used instead of discrete designs. This saves space and cost.

- Alternative Topologies: Cuk, SEPIC and Zeta converters provide input to output isolation, constant input current, and other advantages versus basic buck-boost. Coupled inductor based designs also exist.

Thus the basic buck-boost serves as a foundation for specialized derivatives targeting specific applications. Engineers continue advancing converter technology for increased efficiency, reduced size and cost, and greater reliability.

Conclusion

Buck-boost DC-DC converters offer a flexible solution for generating regulated supply rails above or below an input voltage. This allows creation of voltages needed in electronics even from fluctuating sources. By switching energy pulses through an inductor, high efficiency conversion is possible without the losses seen in linear regulators. Small component sizes miniaturize buck-boosts for use in portable electronics.

The simple architecture also keeps costs low even for high output power designs. Continuing innovation in semiconductors, magnetics, packaging, and control ICs accelerate the capabilities of buck-boost regulators. As engineers discover new applications from microelectronics to electric vehicles, the buck-boost's ability to both step-up and step-down voltages will ensure it remains indispensable in modern power conversion.