Found a better price?

Let us know!

We'll try to match the price for you

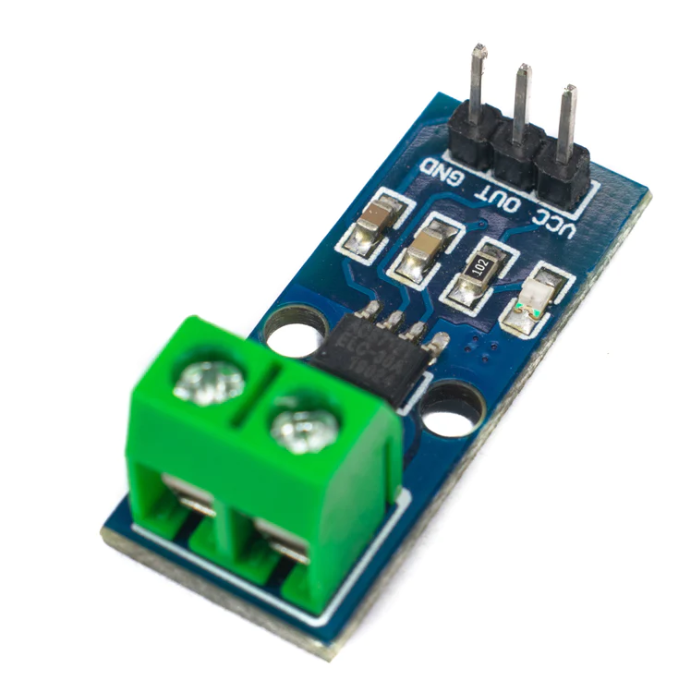

Package Includes:

- 1 x 30A ACS712 Current Sensor

Specifications

| Sensitivity | 66mV/A |

| Measure Current Range | 30A |

| Supply Voltage | 4.5V~5.5V DC |

| Dimensions | 3 x 2 x 1cms |

| Weight | 5 grams |

1.What is ACS712 current sensor?

- The ACS712 is a current sensor that is designed to measure the AC or DC current flowing through a conductor. It is a popular choice for a wide range of applications, including motor control, power supply, and battery-powered systems. The ACS712 consists of a hall effect sensor and a signal conditioning IC, which are packaged together in a single package. The hall effect sensor measures the magnetic field produced by the current flowing through the conductor, and the signal conditioning IC converts the output of the hall effect sensor into a proportional voltage or current.

2.How does ACS712 measure current?

- The ACS712 is a current sensor that uses the principle of the hall effect to measure the AC or DC current flowing through a conductor. The hall effect is the production of a voltage difference across an electrical conductor when it is placed within a magnetic field. The ACS712 consists of a hall effect sensor and a signal conditioning IC, which are packaged together in a single package. The hall effect sensor consists of a thin, flat strip of conductive material that is placed in close proximity to the conductor whose current is being measured. When current flows through the conductor, it creates a magnetic field around it. This magnetic field causes a voltage to be generated across the hall effect sensor, which is proportional to the strength of the magnetic field.

3.Why use ACS712 current sensor?

- There are several reasons why the ACS712 current sensor is a popular choice for many applications:

- Wide current range: The ACS712 is available in several versions, each with a different current range and sensitivity. This makes it suitable for a wide range of applications, from low-current applications to high-current applications.

- Easy to use: The ACS712 is simple to use, as it only requires a single connection to the conductor whose current is being measured. It can be easily connected to an analog input on a microcontroller or other data acquisition system, allowing you to measure and monitor the current flowing through the conductor.

- Compact size: The ACS712 is a small, compact sensor that can be easily integrated into a wide range of applications. This makes it suitable for use in projects where space is at a premium.

- High accuracy: The ACS712 is designed to provide high accuracy measurements, with a typical accuracy of around 1%.

- Versatility: The ACS712 can be used to measure both AC and DC currents, making it suitable for a wide range of applications.

- Overall, the ACS712 is a widely used and respected current sensor that is suitable for a wide range of applications.

4.What does a current sensor do?

- A current sensor is a device that is used to measure the AC or DC current flowing through a conductor. It is a type of electrical transducer that converts the current flowing through a conductor into a proportional electrical signal that can be measured and analyzed. Current sensors are used in a wide range of applications, including motor control, power supply, and battery-powered systems. They are often used to measure and monitor the current flowing through a conductor in order to protect equipment, optimize performance, and ensure safety.

5.Why current sensing is required?

- Current sensing is often required in a wide range of applications for several reasons:

- Protection: Current sensing can be used to protect equipment and ensure safety by detecting and preventing overcurrent conditions. For example, a current sensor can be used to trip a circuit breaker or cut power to a device if the current exceeds a certain level.

- Performance optimization: Current sensing can be used to optimize the performance of a system by providing real-time information about the current flowing through a conductor. This can help to improve the efficiency of a system and extend the life of equipment.

- Monitoring and control: Current sensing can be used to monitor and control the current flowing through a conductor in order to achieve a desired result. For example, a current sensor can be used to control the speed of a motor or the power output of a device.

- Safety: Current sensing can be used to ensure safety by detecting and preventing dangerous or hazardous conditions. For example, a current sensor can be used to detect and prevent electrical fires or shocks.